VOC rotary bed | rotor concentrators

DEC.RBC™

DEC’s innovative Rotary Bed Concentrator (RBC™) technology represents a paradigm shift in volatile organic compound (VOC) emission control, offering unparalleled efficiency and significant cost savings. Our solutions are engineered to handle high-volume, low-concentration airstreams, a challenge for traditional abatement systems. By harnessing advanced temperature swing adsorption and zeolite honeycomb technology, the DEC rotor concentrator efficiently captures VOCs and consolidates them into a small, concentrated stream for downstream treatment. This process drastically reduces the required size and operational expense of VOC emission control plant, such as Thermal Oxidizers (XTOs) and Solvent Recovery Units (SRUs), leading to lower energy consumption and a smaller environmental footprint. DEC's expertise ensures that your VOC abatement system is not only compliant with stringent environmental regulations but also optimized for maximum process efficiency.

Advanced VOC Abatement for Low-Concentration Air Streams • DEC.RBC™

The rotor concentrator (also known as Zeolite Rotor Concentrator) is an auxiliary air pollution control device that works alongside (upstream or downstream) the main VOC treatment system, such as a Solvent Recovery Unit or a Thermal Oxidizer.

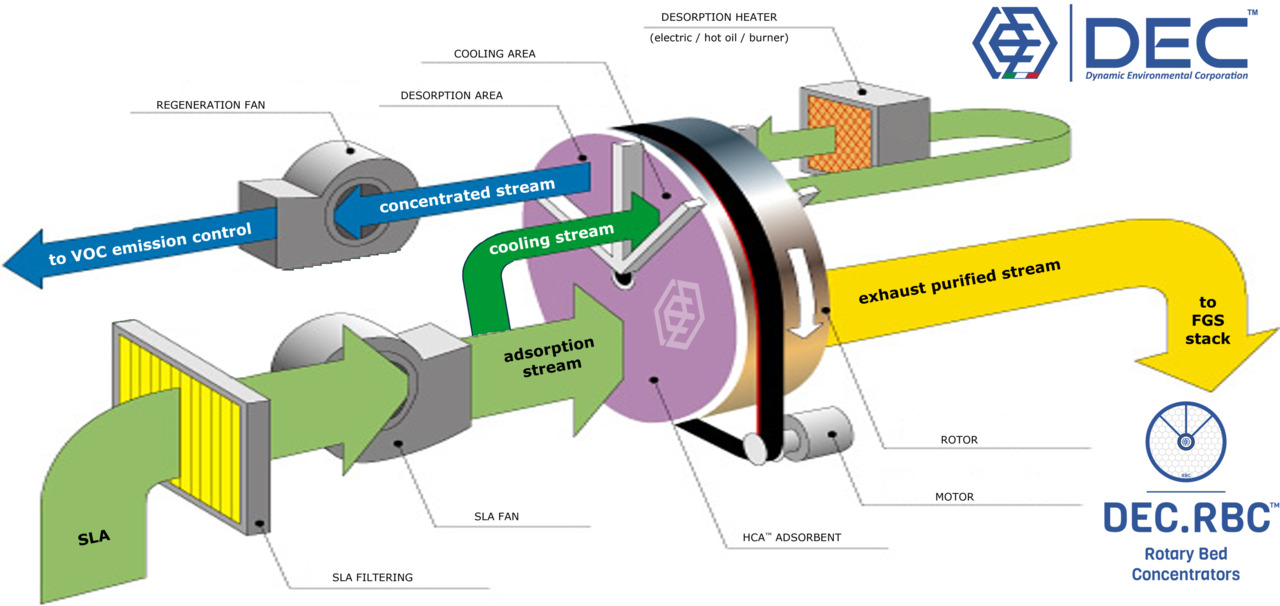

DEC.RBC™ (VOC Rotary Bed Concentrator) is used to remove volatile organic compounds (VOCs) low concentrated air streams: RBCs work by passing the contaminated air stream through a rotating bed of adsorbent material (DEC.HCA™ • Honeycomb Coated Adsorbent), such as zeolite or activated carbon. The VOCs are adsorbed onto the adsorbent, and the clean air stream is then exhausted to the atmosphere through a stack (FGS).

This process is ideal for treating large volumes of solvent-laden air (ranging from 5,000 to 200,000 Nm³/h or more), with small concentration of solvents (typically 0,1 to 2,5 g/Nm3).

VOC Rotary Concentrators: How They Help Reduce Fugitive Emissions • DEC.RBC™

Need to reduce your fugitive emissions and clean large amounts of air with low concentration of solvents? A VOC Rotary Concentrator (DEC.RBC™) can help! Efficiently manage low concentration solvents in large air volumes with our advanced VOC rotary bed (rotor) concentrators, significantly reducing fugitives (often due to equipment leaks and evaporative processes, e.g. floor-sweep) and improving air quality.

Imagine it as a pre-treatment device, attached upstream, before the main VOC abatement system. The concentrator traps the solvents (VOCs) from large solvent laden air (SLA) stream and squeezes them into a smaller, more concentrated stream. This concentrated stream then goes to the main VOC emission control plant, which can be a smaller unit because it has less work to do. The result? Savings on utilities and on CAPEX (reduced sizing of the VOC emission control system)!

VOC Rotary Concentrators: how they work? • DEC.RBC™

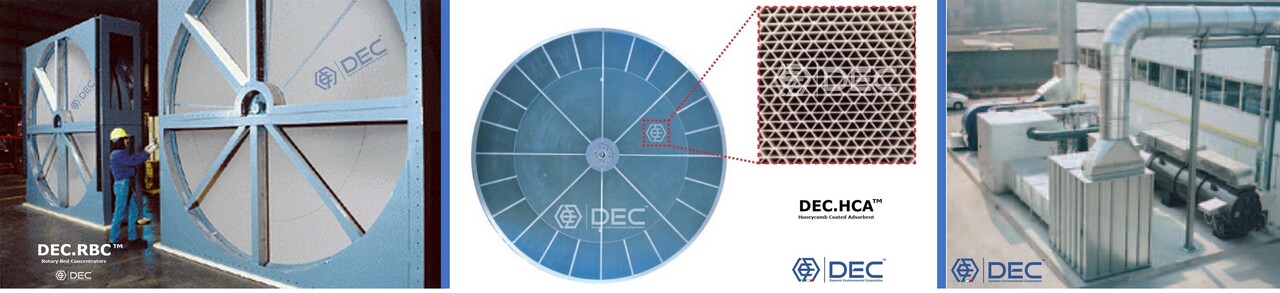

The heart of the DEC.RBC™ unit is a rotating ceramic honeycomb wheel (the rotor) filled with an adsorbent (DEC.HCA™ Honeycomb Coated Adsorbent).

The Solvent Laden Air (SLA) passing through the slowly rotating wheel (1 to 3 rph), comes into contact with the adsorbent bed (~80% of exposed surface), where the VOC are retained. During the rotation, the wheel passes through a regeneration section where hot air desorbs and concentrates the VOC in a flow stream smaller than the original SLA stream.

The rotor wheel is divided into adsorption, desorption, and cooling zones (typically ranging between 8:1:1 to 10:1:1 ratio). The adsorption is typically handled at 20 to 35°C. Desorption through the regeneration (heated) air (typically at 180 to 220°C), while the cooling zone aimed to cool down the DEC.HCA™ Honeycomb Coated Adsorbent to 50°C (or lower) so as to facilitate VOCs adsorption, once back to adsorption phase.

Once concentrated (typically <25% of LEL), the SLA can be efficiently treated in a VOC treatment system: in this way the DEC.RBC™ unit reduces the volume of the SLA of 5 to 20 times while concentrating the VOCs in the same ratio.

benefits • DEC.RBC™

The use of DEC.RBC™ Rotary Bed Concentrators offers several benefits for industrial applications:

available sizes • DEC.RBC™

The DEC.RBC™ unit is built in different diameters, from 1 to 6 meters. Depending on the diameter, these units are provided pre-assembled (DEC.SMS™ - Smart Modular Systems platform), with a capacity 8.000÷50.000m3/h each or partially assembled at the Customer premises with a capacity up to 120.000m3/h cad.).

The size of a zeolite rotor for VOCs purification is usually very large, with some diameters reaching 4 m or more: in this case, the rotor-type adsorber generally consists of a block of spliced fan-shaped honeycomb bodies.

The unit is modular: utilizing, in parallel, more pre-assembled units, it's possible to treat reasonably an air volume equal to ~240.000 m3/h or even more.

For larger applications, thanks to customized design (DEC.CBS™ - Custom Built System), DEC.RBC™ units are modularly assembled on-site, with a capacity ranging from 150.000 ÷ 1.500.000 m3/h.

NOTE: the DEC.RBC™ unit should not be considered as an alternative to LEL Automatic Flow Recirculation Systems (DEC.FRS™).

Contact DEC!

For more information on DEC's VOC sustainable emission control solutions, interfaced with DEC.RBC™ • VOC Rotary Bed Concentrators, please contact DEC.

LTKW • DEC.RBC™

DEC offers superior VOC emission control processes and technologies, including our state-of-the-art Rotary Bed Concentrator. The DEC rotor concentrator is a core component of a modern VOC abatement strategy, providing a cost-effective solution for a wide array of applications. Our systems are the premier choice for high-volume low-concentration VOCs, offering impressive VOC emission reduction efficiency. You can find detailed technical datasheets and information on our custom VOC concentrator systems and DEC VOC concentrator solutions to meet your specific needs. Discover the true benefits of rotor concentrators for VOC abatement, including how they enable substantial rotary concentrator vs RTO cost savings and reduce the overall operating costs of a rotary concentrator and oxidizer. We cover all aspects from the design considerations for rotor concentrator systems and sizing a rotary concentrator system to proper maintenance for Rotary Bed Concentrator units. Interested in how our technology applies to your sector? Learn about zeolite rotary concentrator applications in the automotive paint shops, printing, fiberglass manufacturing, semiconductor manufacturing, and chemical processing industries. Our solutions are designed to address the specific challenges of these sectors, including VOC emission control for composite manufacturing and industrial applications for VOC rotary concentrators, and even odor control. We also provide guidance on troubleshooting Rotary Bed Concentrator issues, and offer Rotary Bed Concentrator installation service. For those considering new investments, our website allows you to easily request a quote for DEC rotary concentrator or a quote for a rotary concentrator system. We can also help with a VOC concentrator system retrofit or help you to compare rotary concentrator technology manufacturers to demonstrate the superiority of the DEC system. Don’t just take our word for it—read a DEC Rotary Bed Concentrator review to see the results our technology can achieve. We provide complete information on how a Rotary Bed Concentrator works and can help you select the most cost-effective VOC abatement technologies for your needs, including integrated systems.