LEL Automatic Recirculation Systems

DEC.FRS™

LEL Automatic Recirculation Systems play an essential role in enhancing safety and efficiency of a converting line, making them a key consideration when planning the installation of a VOC emission control system (e.g. a solvent recovery unit, or a thermal oxidizer).

Increasing energy costs are requesting our customers (flexible packaging and converting industries, using rotogravures, flexo and lamination machines) to explore and evaluate energy saving technologies, in order to increase their competitiveness in the global market.

DEC.FRS™ • Flow Recirculation Systems in drying hoods maximize efficiency, enhance safety, and minimize environmental impact in the converting industries: we provide a comprehensive and flexible solution to achieve these goals, empowering industries to optimize your VOC emission control systems and gain a competitive edge in the global market.

Drying hoods are essential components of converting processes, removing solvents from materials such as film, paper, and textiles. However, traditional drying hood designs often suffer from inefficiencies, safety hazards, and environmental concerns. These challenges stem from the suboptimal airflow patterns and inadequate control over VOC emissions.

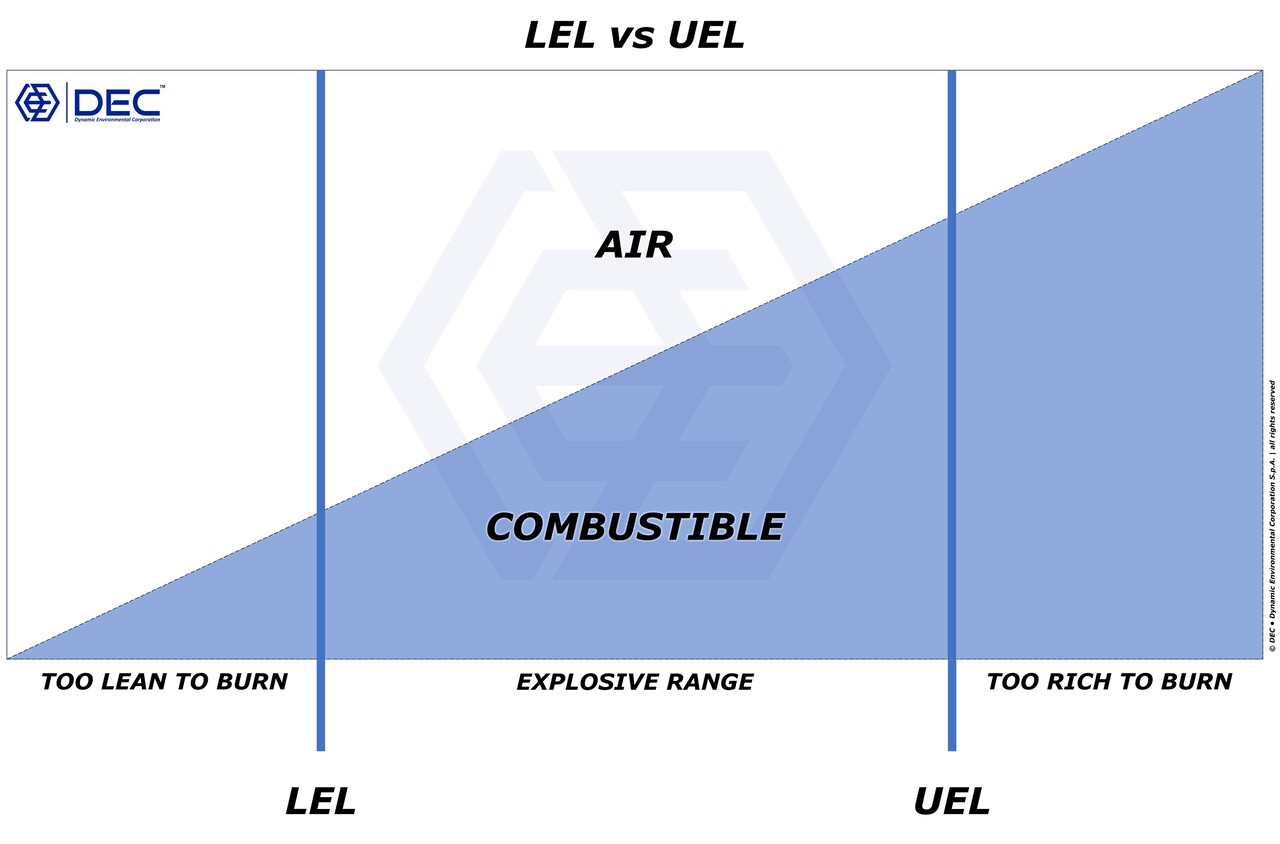

Increased converting speeds, often associated with the application of special and background colors and heavy coatings (high ink coverage), lead to elevated solvent concentrations in the exhaust air stream. Obstructions in the inlet air path, such as those caused by dust accumulation or exacerbated by poor maintenance practices, can reduce airflow to the dryer, further increasing solvent concentration in the exhaust. High solvent concentrations pose a significant explosion risk in both the dryer and the exhaust system. Therefore, continuous monitoring of solvent concentration (LEL) in the converting line is essential.

DEC.FRS™ • LEL Automatic Recirculation Systems | how it works?

Automatic recirculation systems work in conjunction with LEL monitoring systems to continuously measure and optimize the solvent concentration in the exhaust air, ensuring safety and efficiency of the dryers. These systems use LEL sensors to analyze the gas sample and provide real-time data on solvent concentration levels.

Every drying station is equipped with its own dedicated supply (fresh-air inlet) and suction (exhaust) fans: using an interconnecting duct between the dryers’ inlet and outlet, through modulating dampers, the DEC.FRS™ manages the recirculation of air based on the solvent concentration within the drying stations. This setup regulates the hot air being reused while continuously monitoring and maintaining solvent levels within safe limits.

When the solvent concentration in the exhaust air is below a set safety limit (typically expressed as LEL%), the DEC.FRS™ system automatically recirculates a portion of the hot exhaust air back into the drying process. This reduces the need to heat "fresh air," resulting in significant energy savings and a reduced volume of exhaust SLA (Solvent Laden Air) flow.

In drying hoods for packaging operations, DEC.FRS™ can reach very high recirculation rates (up to 100%, in specific configurations) where all dryer injected/exhausted air is returned to the "fresh air" intake. Despite this, an outlet flow persists due to "false air" inlet. In modern systems, advanced machine design minimizes false air infiltration. However, because the printing element is maintained under slight negative pressure to reduce fugitive emissions, a continuous outlet flow remains, even at maximum recirculation efficiency. This flow, combined with the uncirculated stream, is directed to the VOC emission control system for treatment.

DEC.FRS™ • LEL Automatic Recirculation Systems | benefits

DEC.FRS™ • LEL Automatic Recirculation Systems | modularity

FRS™ systems are engineered for modularity and compactness, with sensors that effortlessly integrate alongside a variety of ducts, ovens, dryers, or enclosures. These units are suitable for field mounting or panel installation, offering a streamlined, space-efficient design that eases maintenance. They can be fitted with either local or remote displays and alarms.

DEC.FRS™ • LEL Automatic Recirculation Systems | compatibility

Our retrofit solutions are compatible with all laminating, coating, flexo, and gravure presses. While some dryer ventilation system adjustments may be necessary, our expert engineers will conduct a thorough inspection to provide a detailed report. This report will include the total dudget investment, an estimation of the resulting discharge SLA flow rate reductions, estimated annual energy savings, and the project's payback period (ROI).

Our retrofit solutions are exclusively designed for existing converting lines: we do not offer or apply retrofits to recent/new converting lines. Integrating such systems into a new line requires deep interfacing with the original operating software, and any unauthorized modifications could void certifications and potentially compromise safety. For new converting lines, any desired modifications or upgrades should be performed directly by the original manufacturer (OEM) of the converting line.

DEC.FRSx™ • LEL Automatic Recirculation Systems | control loop

The DEC.FRS™ system's response to a Lower Explosive Limit (LEL) exceeding the set threshold (H/HH) depends on the chosen configuration. Here's a breakdown of the three available options:

DEC.FRS™ • LEL Automatic Recirculation Systems | single & multi-line

Three different FRS™ control and recirculation processes are available:

DEC.FRS™ • floor sweep management

To reduce fugitive emissions, floor sweep can be managed with different approaches:

DEC.FRS™ • LEL Automatic Recirculation Systems | sensors

Discover the diverse array of sensor technologies available for implementation, including infrared (IR) and flame ionization detectors (FID).

The use of catalytic LEL sensors must be avoided because the catalyst can be poisoned by specific compounds within the chemicals (e.g., inks, varnishes, adhesives), including functional additives, amines, and general impurities.

DEC.FRS™ • LEL Automatic Recirculation Systems | compliance

EN 1539 (Dryers and ovens, in which flammable substances are released – Safety Requirements) specifies safety measures for equipment where flammable vapors are generated. It mandates explosion protection strategies, including ventilation and monitoring systems to keep vapor concentrations below 25% of the LEL under normal conditions (or higher with additional safeguards). For control systems performing safety functions, EN 1539 references ISO 13849-1 (Safety of machinery, safety-related parts of control systems) to ensure their reliability, particularly when automatic controls are integral to explosion prevention.

DEC.FRS™ can optionally be provided in compliance with "PL d" of ISO 13849-1, featuring a durable, fault-tolerant design specifically engineered to address the explosion hazards detailed in EN 1539. By incorporating highly reliable components and advanced diagnostics, the system guarantees safe performance in high-risk settings. DEC meticulously records every phase—risk assessment, design, and validation—to substantiate compliance, harmonizing operational efficiency with rigorous safety requirements.

DEC.FRS™ • LEL Automatic Recirculation Systems | challenges

Retrofitting a solvent drying hood with a Flow Recirculation System (FRS) controlled by a Lower Explosive Limit (LEL) sensor is a significant technological and safety upgrade. This system recycles a portion of the solvent-laden air back to the dryers, reducing the volume of fresh air needed. This leads to substantial savings in energy consumption both heating and VOC emission control system (oxidizer or solvent recovery). However, implementing such a system requires a planned shutdown of the production line(s), which presents several challenges that must be addressed.

A successful drying hoods retrofit hinges on the careful planning and execution of a controlled shutdown. This is necessary to perform critical modifications that cannot be completed while the lines are operational. The key challenges include:

Any initial budget for a retrofit project is an indicative proposal only. The actual costs can vary significantly based on the specific conditions of each machine and facility. Factors that influence the final price include:

Therefore a site visit to perform a detailed inspection of the machinery and site layout is mandatory. This allows for a dedicated assessment of the required modifications and a reliable quotation. This ensures that all major challenges and opportunities are identified and addressed, providing a clear and reliable path forward for this essential upgrade.

DEC.FRS™ • LEL Automatic Recirculation Systems | conclusions

LEL automatic recirculation systems (DEC.FRS™) play a crucial role in ensuring safety and efficiency in printing and laminating processes. By continuously monitoring solvent concentration levels and automatically recirculating exhaust air, these systems help prevent explosions, reduce energy consumption, and improve operational efficiency.

contact DEC

Contact DEC for a consultation: we can help you assess your needs and recommend the best Advanced Flow Optimization technology for your operation.