Solvent Recovery: DEC Advanced Sustainable Solutions for VOC & HAP Emissions Control

Solvent Recovery Unit ♻️ Solvent Recovery Plant ♻️ Solvent Recovery System

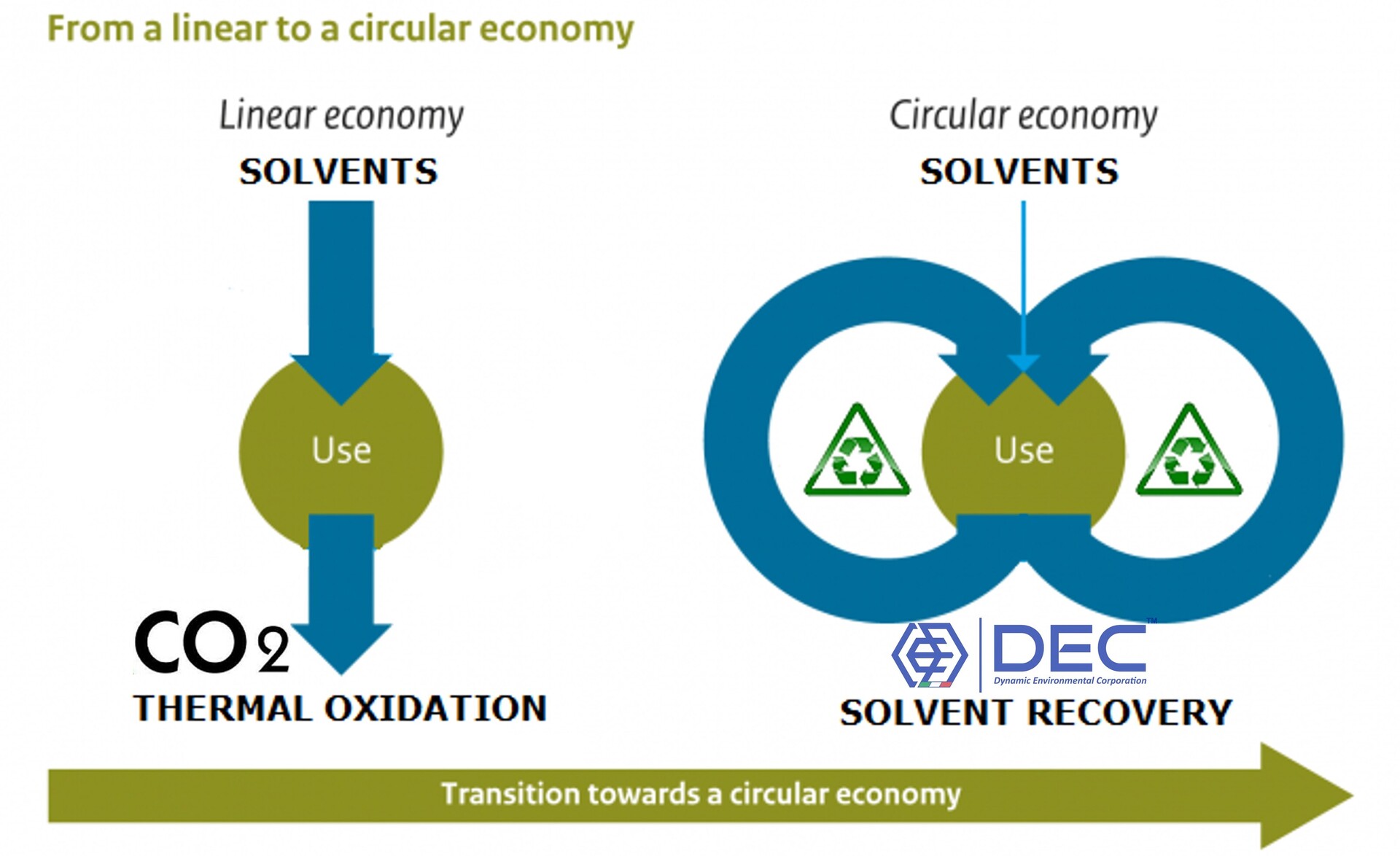

The Essential Role of DEC Solvent Recovery in a Circular Economy

Solvent Recovery is a critical process, and Solvent Recovery Units (SRU), also known as Solvent Recovery Plants (SRP) or Solvent Recovery Systems (SRS), are APC air pollution control devices employed in solvent-based manufacturing processes to control air emissions of solvents (VOCs Volatile Organic Compounds and HAPs, Hazardous Air Pollutants from solvent-laden air or vapor) to comply with global, regional and local environmental regulations and directives.

Looking for the best VOC emission control technologies? DEC Solvent Recovery (SRUs) stand out as a top choice for industries aiming to reduce VOC emissions efficiently and sustainably. Whether you’re curious about how DEC Solvent Recovery control VOC emissions or ready to implement a Solvent Recovery for VOC emission solutions, these systems offer unmatched benefits. With high recovery rates of up to 99%, compliance with strict regulations, and significant cost savings, SRUs lead the pack in DEC Solvent Recovery VOC emission control technology. Browse and click to explore why they’re the ultimate solution for your VOC reduction needs and boost your environmental performance today!

Solvent Recovery (DEC.SRU™) are designed to meet the stringent regulatory requirements pertaining to VOC air emissions. Volatile Organic Compounds, emitted during various industrial processes, contribute significantly to air pollution and are subject to strict environmental controls. The DEC.SRU™ acts as a robust solution for industries seeking to minimize their environmental footprint by efficiently capturing and recovering these VOCs.

By incorporating advanced technologies, DEC Solvent Recovery Unit ensures that the released air is within permissible limits, aligning with environmental regulations: this not only helps industries comply with stringent VOC emission standards but also promotes a cleaner and healthier environment for surrounding communities, while saving up to 90% on solvent costs.

DEC is offering several decades of experience in design and installation of the most technically advanced and efficient vapor phase activated carbon solvent recovery systems.

Solvent Recovery (DEC.SRU™) • processes & technologies

The following desorption technologies & regeneration processes are available:

DEC Solvent Recovery (SRUs) are available in both skid modular layout (DEC.SRU_SMS™ • Smart Modular Systems, pre-built and pre-tested at our workshops) or in full customizable version (DEC.SRU_CBS™ • Custom Built Systems, with on-site erection).

Solvent Recovery (DEC.SRU™) • benefits

Apart from its environmental advantages, the Solvent Recovery (DEC.SRU™) offers compelling economic benefits by enabling the recovery and direct reuse of solvents. Solvents play a vital role in various manufacturing processes, and their efficient use is crucial for cost-effective production. By allowing for the direct reuse of recovered solvents, the DEC.SRU™ significantly reduces the need for new solvent purchases.

The cost savings achieved through solvent recovery contribute to an impressive Return on Investment (ROI) 📊. Industries adopting the Solvent Recovery (DEC.SRU™) can experience a substantial reduction in operational costs related to solvent procurement, subsequently enhancing their overall financial performance.

The Solvent Recovery (DEC.SRU™) also generates significant savings by offering a sustainable alternative to the conventional practice of thermal oxidation (DEC.XTO™). Rather than incurring the expenses associated with purchasing fresh solvents, industries can capitalize on the cost-effective option of reusing recovered solvents. This sustainable approach delivers benefits that extend beyond immediate savings on solvent procurement, positively impacting the overall profitability and competitiveness of manufacturing operations.

|

|

Solvent Recovery (DEC.SRU™) • contact DEC

If you are looking for a reliable and efficient solvent recovery, DEC.SRUs™ (Solvent Recovery Units) are the right and best option: DEC.SRUs™ are the most advanced and reliable Solvent Recovery on the market, with processes, configurations and options to meet the needs of different applications, present and future challenges.

Feel free to contact DEC: we can help you assess your needs and recommend the best Solvent Recovery for your operation.