LEL (Lower Explosive Limit) • detection | monitoring | control

DEC.LEL™

LEL (Lower Explosive Limit) monitoring and automatic recirculation systems play a critical role in ensuring safety and optimizing operational efficiency. Furthermore these systems are a crucial element to be evaluated when you are planning to install a VOC emission control system (e.g. a solvent recovery unit, or a thermal oxidizer).

Increasing energy costs are requesting our customers (flexible packaging and converting industries, using rotogravures, flexo and lamination machines) to explore and evaluate energy saving technologies, in order to increase their competitiveness in the global market.

Ensure the safety and efficiency of your operations with DEC's advanced solutions for VOC emission control technologies, featuring integrated LEL (Lower Explosive Limit) detection, precise monitoring, and proactive control. Our cutting-edge systems are engineered to provide real-time insights into flammable gas concentrations, mitigating the risks associated with volatile organic compounds. By implementing our robust LEL detection and monitoring capabilities, you can achieve unparalleled safety, optimize your VOC control processes, and comply with stringent regulatory standards. Trust DEC for comprehensive solutions that safeguard your personnel and assets while ensuring environmental responsibility in VOC emission control.

DEC.LEL™ • what is a LEL detector?

An LEL detector, or LEL meter, is a process analyzer (DEC.ATX™) that quantifies dangerous levels of combustible gases or solvent vapors in the air, expressed as a percentage of the Lower Explosive Limit (LEL). It serves as an essential element within a complete gas detection system.

DEC.LEL™ • measured values (%)

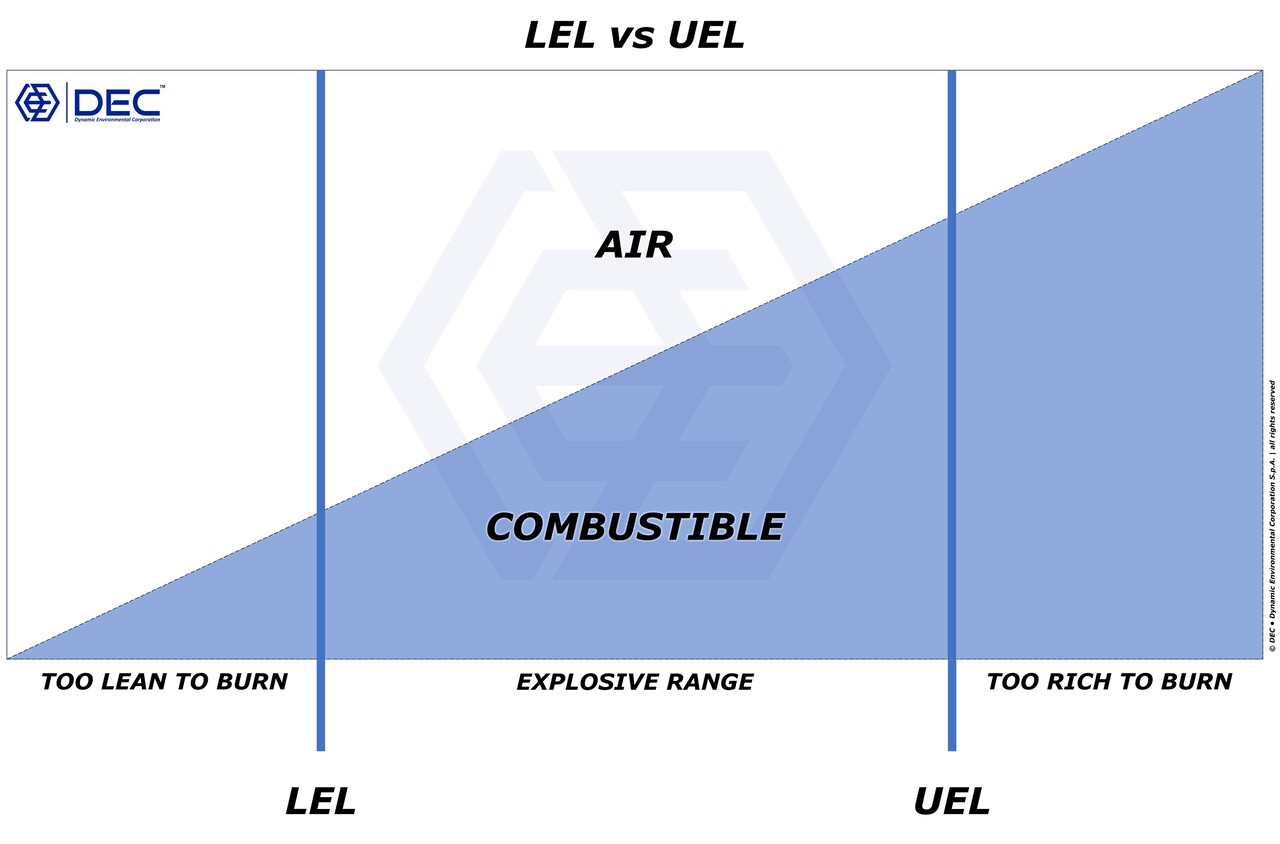

Explosivity is typically measured in %LEL (0-100% LEL), where 100% means the gas concentration has reached the lower explosive limit and became explosive.

DEC.LEL™ • key terms

DEC.LEL™ • Monitoring Technologies

The following LEL monitoring technologies are part of our DEC.ATX™ portfolio:

DEC.LEL™ • LTKW

DEC offers a comprehensive suite of VOC emission control technologies incorporating critical LEL (Lower Explosive Limit) detection, continuous monitoring, and effective control. Understanding what is LEL in VOC emission control is paramount, and our systems provide the tools for thorough LEL monitoring in industrial VOC control, adhering to the best practices for LEL control in VOC abatement systems. The importance of LEL monitoring for VOC safety cannot be overstated, and DEC provides various LEL sensor types for VOC detection explained with clear operational guidelines, including how to calibrate LEL detectors for VOC monitoring. Addressing potential issues is key, and our solutions help in troubleshooting common LEL monitoring system issues while meeting stringent regulatory standards for LEL in VOC emission control. Recognizing what are the risks of exceeding LEL in VOC environments, our technologies focus on integrating LEL detection with VOC control systems using advanced LEL monitoring techniques for VOCs. We emphasize the role of LEL in preventing VOC explosions and consider factors affecting LEL readings in VOC monitoring, comparing different LEL control methods for VOCs and incorporating the latest innovations in LEL detection technology for VOCs. Our safe operating procedures for VOC control with LEL monitoring account for variables like how temperature affects LEL of common VOCs and whether humidity can impact LEL detection accuracy for VOCs, offering even remote LEL monitoring solutions for VOC emission control.

get a consultation

LEL monitoring and automatic recirculation systems are not just safety measures, but also energy-saving solutions that can significantly benefit businesses in the flexible packaging and converting industries. They ensure regulatory compliance, enhance safety, and contribute to cost reduction through improved operational efficiency.

Contact DEC for a consultation: we can help you assess your needs and recommend the best Advanced Flow Optimization technology for your operation.