VOC Emission Control Regulations in India

Regulatory Compliance and Enforcement

The Air (Prevention and Control of Pollution) Act (1981) and the Environment (Protection) Act (1986), are the cornerstone of air quality regulation in India, focusing on pollutant emissions.

The Act defines "air pollutant" as "any solid, liquid or gaseous substance present in the atmosphere in such concentration as may be or tend to be injurious to human beings or other living creatures or plants or property or environment": this comprehensive definition includes Volatile Organic Compounds (VOCs). Section 22 of the Air Act prohibits any industry from allowing the emission of any air pollutant in excess of the standards laid down by the Government.

The Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) are empowered to enforce emission standards for industries and sources.

The CPCB notifies the emission standards for various industrial sectors that are significant sources of VOCs: these standards often specify maximum permissible average concentration limits for key VOCs in industrial stack emissions.

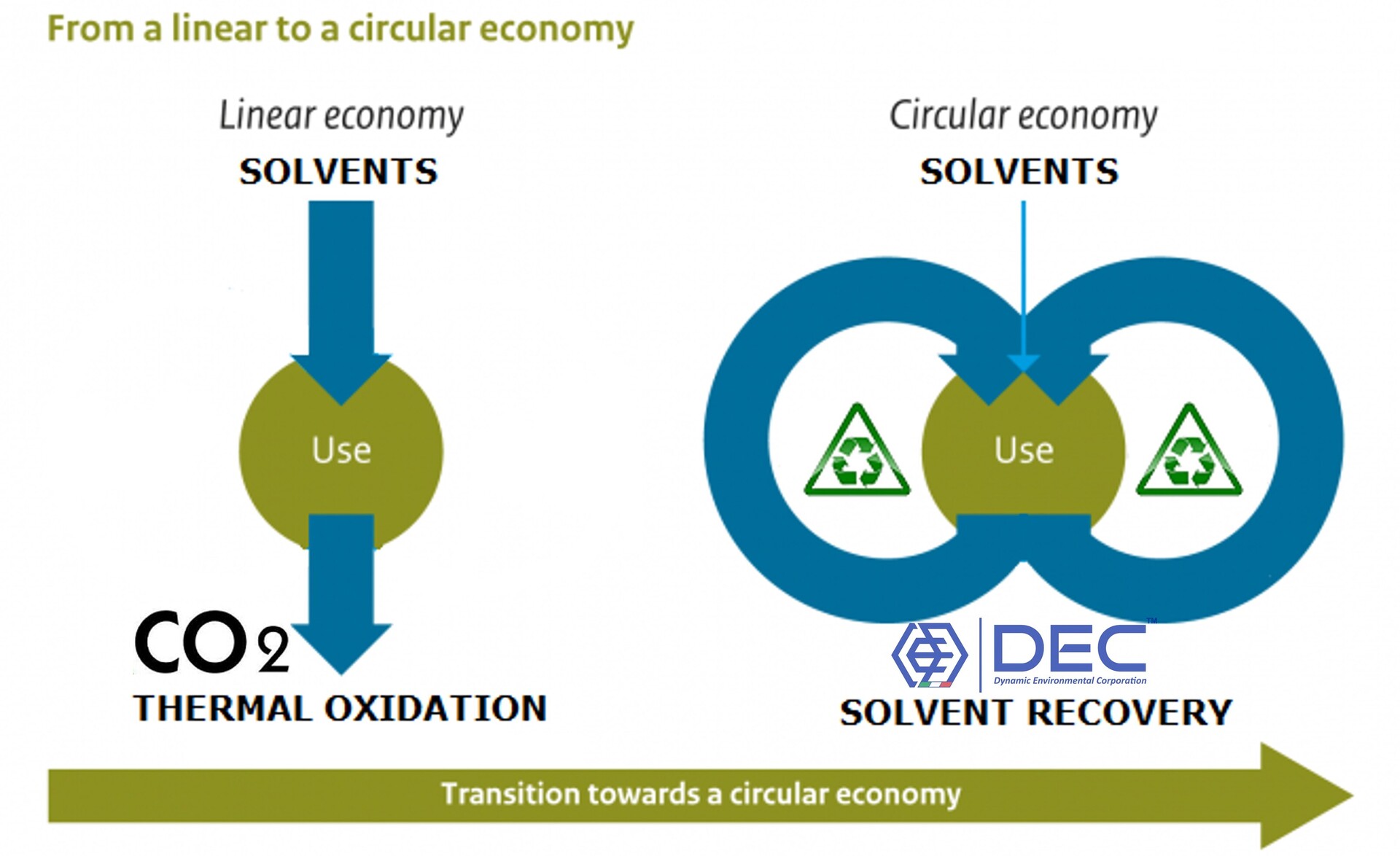

The NAAQS encourages and often mandates industries with high solvent usage to adopt a circular approach through Solvent Recovery process, dictating Standard Operating Procedures (SOPs).

What Are VOCs and Why Does the Air Act Target Them?

Volatile Organic Compounds (VOCs) are a broad class of organic chemical vapors that are released into the atmosphere from various sources, especially the evaporation of solvents, inks, and adhesives.

The regulatory mandate is simple: industries must not allow the emission of any air pollutant, including VOCs, in excess of the standards laid down by the SPCB (Section 22).

🏭 Industrial Focus: VOC Compliance for Solvent Users

For high-VOC emitting sectors, such as printing, flexible packaging, coating, lacquering, chemical manufacturing, and oil & gas, compliance hinges on achieving a minimum Destruction and Removal Efficiency (DRE) of 95% or meeting a prescribed stack emission limit, often around 100mg/Nm3 for Total VOCs (TVOCs).

To meet these tight limits, industries must adopt robust Air Pollution Control (APC) systems.

Key Compliance Requirement: Consent to Operate (CtO)

Every industrial plant must obtain a Consent to Operate (CtO) from the respective SPCB (Section 21 of the Air Act). The CtO specifies the allowed emission limits, the required control equipment, and the monitoring frequency, making it the most critical document for ensuring VOC compliance.

⚙️ Essential Air Pollution Control (APC) Systems for VOC Abatement

Air Pollution Control (APC) refers to the measures, techniques, and technologies employed to reduce or eliminate the emission of pollutants into the atmosphere; the primary goal of APC is to improve overall air quality and comply with legal emission standards, and particularly:

Choosing the right APC system is vital for achieving and maintaining compliance while managing operational costs.

The primary technologies used in India for VOC abatement fall into two categories:

🚨 General Air Act Enforcement Protocol

The legal mechanism is firmly in place for VOC violations, which would apply directly to industries not complying:

✅ Steps to Ensure VOC Compliance Under the Air Act

For industries in India, proactive measures are key to seamless operation and avoiding penalties enforced by the CPCB/SPCBs:

🤝 Partner with DEC

India’s environmental laws are constantly evolving. Partnering with experienced environmental consultants and APC system providers is crucial to designing a compliance strategy that is both legally sound and energy efficient.

At DEC, we understand the critical importance of VOC Emission Control systems: as the leader in the field, we have honed our expertise over the years to offer you the most advanced and efficient technologies available today. Our commitment lies in providing value-driven solutions that not only meet your business requirements but also contribute to a cleaner and greener future.

By harnessing our decades of experience and relentless pursuit of innovation, we have developed a comprehensive range of tailor-made systems for your unique challenges. Our state-of-the-art technologies ensure optimal batement efficiencies, allowing you to maximize your resources, reduce costs, and minimize environmental impact.

Partnering with DEC means unlocking a world of possibilities. Our team of experts is dedicated to understanding your specific needs and delivering customized solutions that align seamlessly with your operations. We believe in building strong, long-lasting relationships with our clients, supporting you every step of the way on your journey towards sustainable success.

Explore our website to discover the transformative power of our VOC Emission Control solutions: witness firsthand how our innovative technologies can help you optimize your production processes, improve efficiency, and achieve significant cost savings. Together, let's pave the way for a brighter, greener future.

Together, we can make a difference.

✉️ contact us

If you are looking for a reliable and efficient Air Pollution Control process, check DEC.APC™ processes, configurations and options to meet the needs of different applications, present and future challenges.

Feel free to contact DEC: we can help you assess your needs and recommend the best Air Pollution Control (APC) technology for your operation.