Solvent Storage Tanks

DEC.SST™

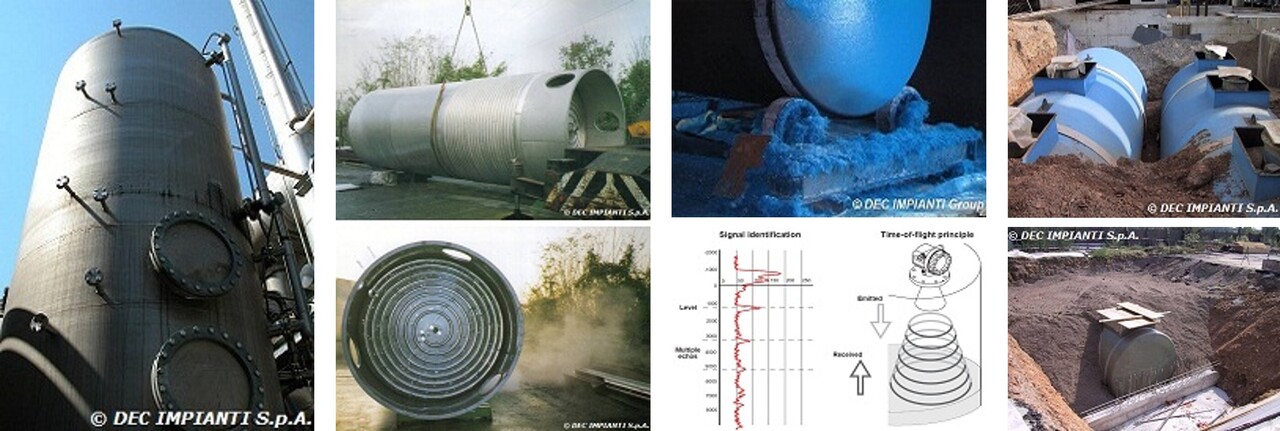

Solvent storage tanks are critical components in industries such as chemical manufacturing, pharmaceuticals, and petrochemicals, where safe and efficient storage of solvents is essential. These tanks are designed to store flammable and non-flammable liquids while adhering to strict safety and environmental standards. We explore the construction, standards, and types of solvent storage tanks, focusing on their materials, design features, and applications.

Solvent Storage Tanks • DEC.SST™

Solvent storage tanks are predominantly constructed from stainless steel, specifically grades AISI-304 or AISI-316, due to their excellent corrosion resistance and durability. These materials ensure compatibility with a wide range of solvents, preventing chemical reactions that could compromise the tank’s integrity or the stored liquid’s quality. The choice of grade depends on the solvent’s corrosiveness, with AISI-316 often preferred for more aggressive chemicals due to its higher molybdenum content, which enhances resistance to pitting and crevice corrosion.

The design and fabrication of solvent storage tanks are governed by stringent international standards (e.g. EN-12285, DVS 2205, API, ASME) to ensure safety, reliability, and environmental compliance, providing comprehensive guidance on material selection, wall thickness, quality control, and testing protocols, ensuring that tanks meet rigorous safety and performance benchmarks.

Solvent Storage and Distribution systems • DEC.SSD™

For additional configurations, please check DEC.SSD™ • solvent storage and distribution systems.