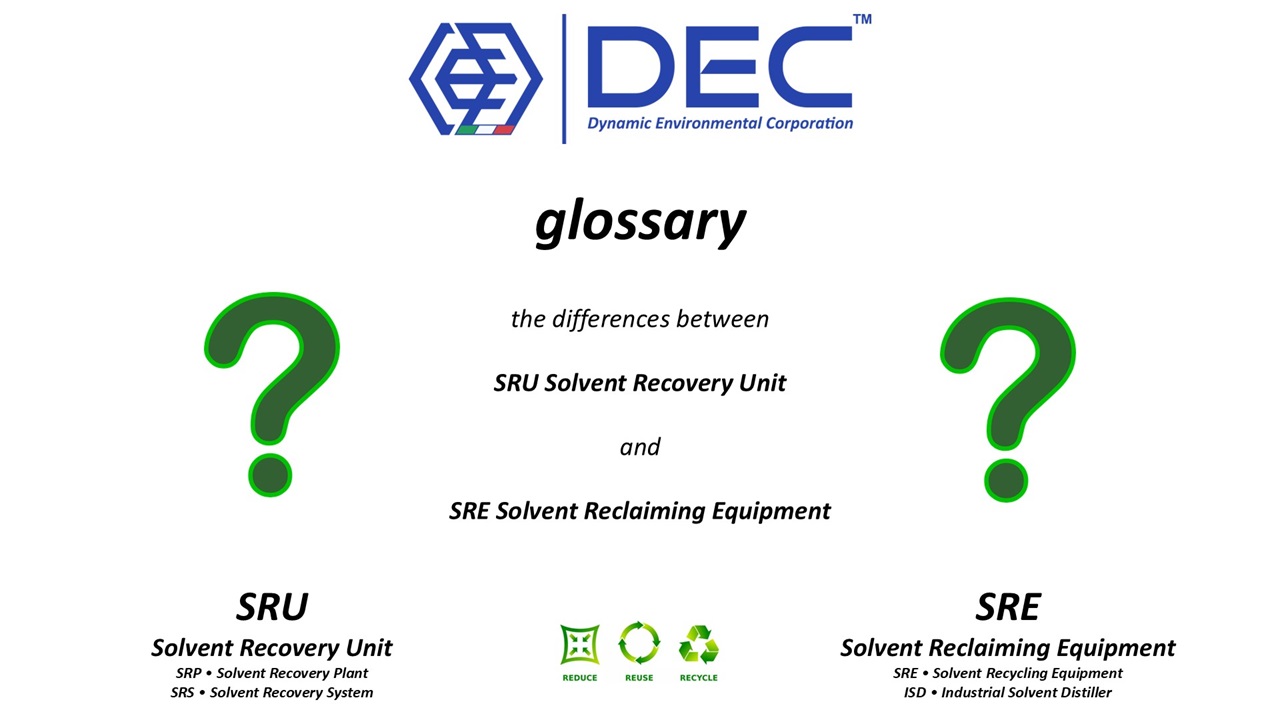

SRU Solvent Recovery Unit | SRE Solvent Reclaiming Equipment

understanding the differences

glossary

Solvent Recovery Units (SRU), also known as Solvent Recovery Plants (SRP) or Solvent Recovery Systems (SRS), have totally different application than Solvent Reclaiming Equipment, SRE, also known as Industrial Solvent Distillers (ISD).

The main difference between a Solvent Recovery Unit (SRU) and Solvent Reclaiming Equipment (SRE) is their application. However, both SRU and SRS share the same goal: recovering valuable solvents from industrial processes, while generating a positive return on investment (ROI), minimizing VOC emissions and solvent waste, while improving the social performance, and reducing the environmental footprint (TBL, triple bottom line).

SRU • Solvent Recovery Units

Solvent Recovery Units (SRU) (also known as Solvent Recovery Plants (SRP) or Solvent Recovery Systems (SRS)) is a gas phase VOC adsorption system, based on activated carbon adsorption, complete of onsite desorption technology, typically employed as VOC Emission Control, allowing the compliance to VOC emission limits (e.g. EU IED | Industrial Emission Directive, US CAA | Clean Air Act, etc.) with very high efficiency (up to 99%), while recovering the solvents for direct reuse, at a fraction of their purchase cost, generating a very interesting ROI (a sustainable technology and a true path to decarbonization). They can cover from small to large SLA (Solvent Laden Air) volumes and deal with a wide variety of VOCs, mixed or alone, including water-miscible, non-water-miscible solvents.

SRE • Solvent Reclaiming Equipment

Solvent Reclaiming Equipment (SRE) (also known as Solvent Recycling Equipment or Industrial Solvent Distiller (ISD), is designed for in-house batch operation, allowing the separation of useful solvents from effluents (e g. inks, paints, lacquers, adhesives, etc.), waste solids, and other contaminants. The SRE (Solvent Reclaiming Equipment) typically employs a distillation process (atmospheric or vacuum) which involves heating the waste fluid to vaporize the solvent, then cooling and condensing the vapors back into liquid form, recycling a significant portion of the solvents for reuse (in the process or for industrial cleaning purposes).

conclusions

When considering solvent recovery technologies, there is no single "best" choice for your operation: in some cases, it is usually be beneficial to have both DEC.SRU (Solvent Recovery Unit) and SRE (Solvent Reclaiming Equipment) installed, allowing the industries to maximize the recovery of solvents for reuse, leading to significant savings in terms of both cost and environmental impact.