Cooling Fill Pack

DEC.CFP™

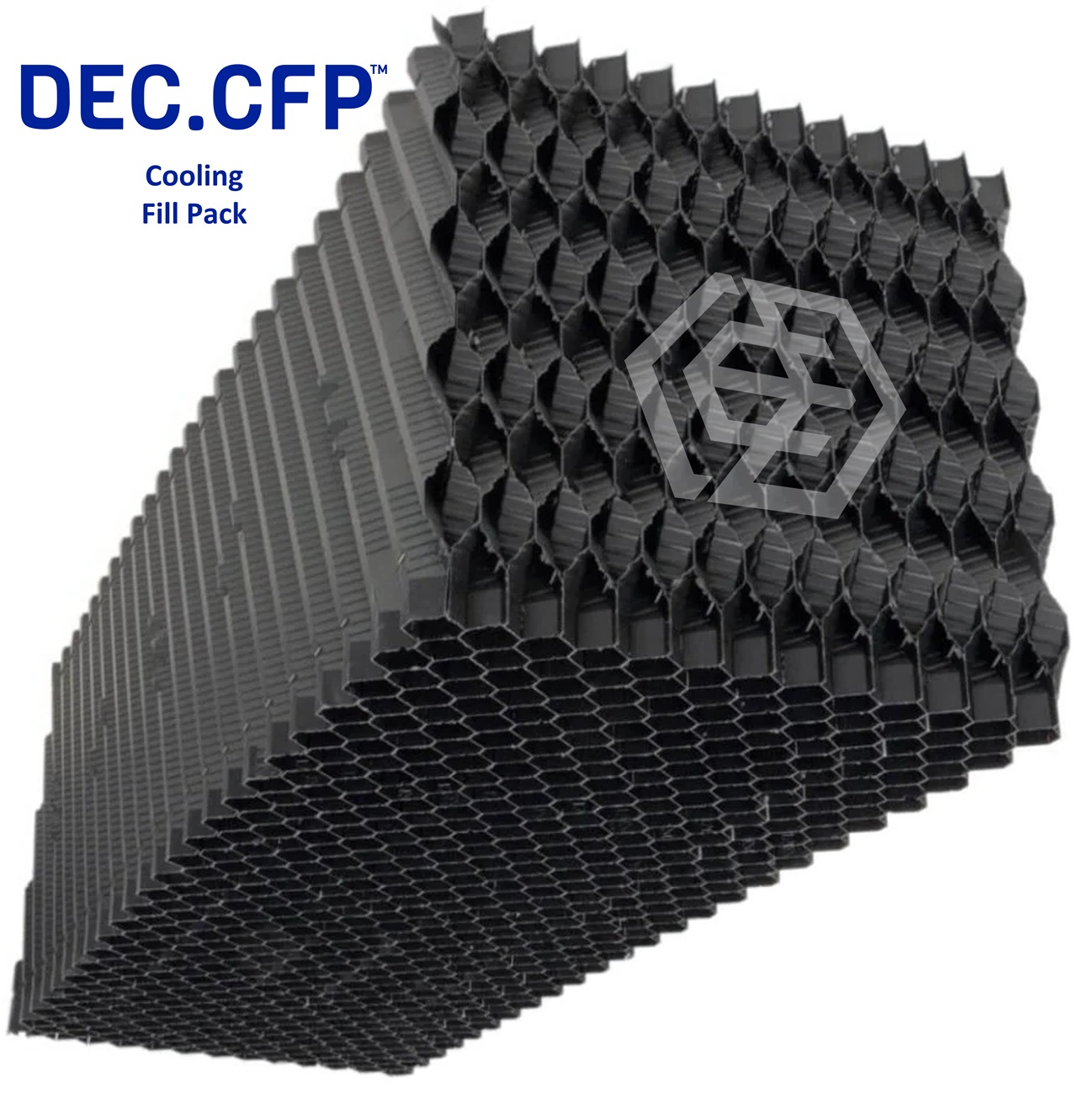

Cooling towers are indispensable components in numerous industrial processes, from power generation to HVAC systems. Their efficient operation hinges on the ability to effectively dissipate heat, and at the heart of this process lies the fill pack. Over time, however, these vital elements can become compromised, leading to decreased performance and increased operational costs.

Fill Pack Functionality • DEC.CFP™

Fill Pack (also known as fill or packing) is a material placed inside a cooling tower (DEC.CWS™) to increase the contact surface area between water and air. By maximizing this contact, fill promotes efficient heat transfer, leading to effective cooling. It essentially slows down the water flow, allowing more time for evaporation and heat exchange. Fill packs are designed to maximize the surface area of water exposed to airflow within the cooling tower. This increased surface area facilitates efficient evaporative cooling, which is the primary mechanism for heat rejection. The fill pack's design, including its material, shape, and spacing, directly impacts the tower's thermal performance.

The primary function of a cooling tower fill pack is to:

Fill Pack Types • DEC.CFP™

Fill materials and designs vary depending on the application and cooling requirements. There are primarily two main types of fill packs:

Fill Pack Materials • DEC.CFP™

The materials used for fill must be durable, corrosion-resistant, and capable of withstanding the harsh environment within a cooling tower. Common materials include:

Fill Pack contamination

Despite their robust design, cooling tower fill packs are susceptible to contamination over time. This contamination can significantly impair their performance and lead to several issues:

Fill Pack optimized performance • DEC.CFP™

The DEC.CFP™ product line is engineered to address these challenges, offering high-performance fill pack solutions designed for longevity and efficiency. However, even with high-quality materials and design, periodic replacement is essential to maintain optimal cooling tower performance.

Contact DEC!

For more information about DEC.CFP™ • Cooling Fill Pack, please contact DEC.