Carbon Molecular Sieves

DEC.CMS™

Carbon Molecular Sieves | intro

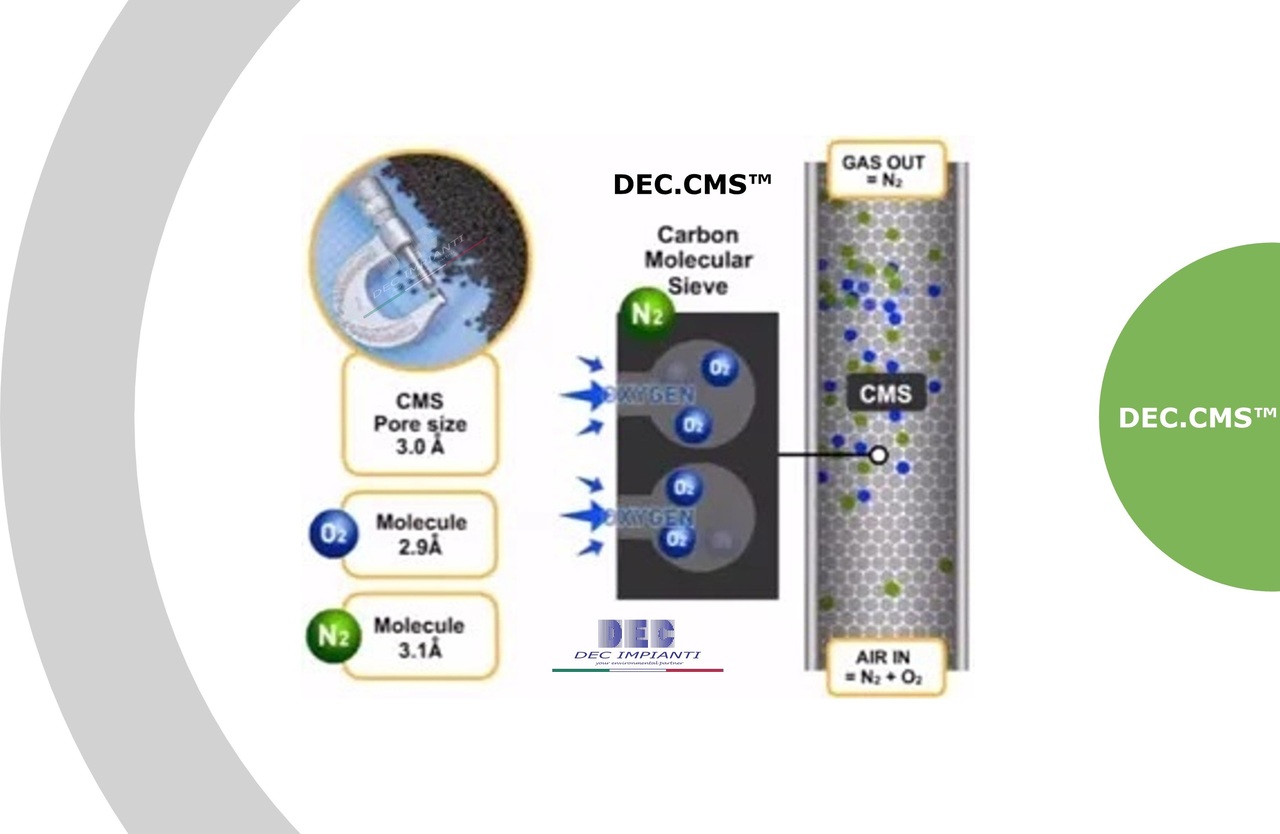

Carbon Molecular Sieves (CMS) are advanced carbonaceous adsorbents engineered for selective gas separation. Characterized by a uniform micropore structure, CMS excel in separating gas molecules based on differences in diffusion rates, making them a cornerstone of industrial processes like nitrogen generation. Produced from carbon-rich precursors such as coconut shells, coal, or polymers via pyrolysis and activation, CMS offer a sustainable and efficient solution for gas purification and separation.

Discover the power of carbon molecular sieves in nitrogen generation for efficient, cost-effective gas separation. Whether you’re curious about how do carbon molecular sieves work or seeking the best CMS for nitrogen generation, these advanced materials deliver high-purity N2 (up to 99.995%) via the carbon molecular sieve PSA process. With benefits like energy efficiency and durability, CMS outshine alternatives—perfect for industries needing reliable nitrogen supply. Ready to explore CMS nitrogen generation efficiency or buy carbon molecular sieves for N2? Dive into our expert insights and top-tier solutions to elevate your operations today!

Carbon Molecular Sieves | Structure and Properties

CMS are defined by their narrow pore size distribution, typically ranging from 3 to 5 Ångstroms (Å), which enables molecular sieving. This distinguishes them from activated carbon, which has a broader pore range (average ~20 Å). The micropore volume of CMS is approximately 0.15–0.25 cm³/g, with surface areas of 250–400 m²/g. Their slit-shaped pores, formed by planar aromatic structures, provide high selectivity by allowing smaller molecules (e.g., O2, 0.346 nm) to diffuse faster than larger ones (e.g., N2, 0.364 nm). CMS exhibit excellent mechanical stability (hardness >98 wt%) and thermal resistance, enduring pressure swings and high-temperature environments without degradation.

Carbon Molecular Sieves | how it works

CMS operate via kinetic separation, leveraging the differential adsorption rates of gas molecules. In a typical Pressure Swing Adsorption (PSA) system, compressed air is introduced to CMS-filled columns. Oxygen (O2), with its smaller kinetic diameter, is preferentially adsorbed into the micropores, while nitrogen (N2) passes through, yielding high-purity N2 (97–99.995%). The process cycles between adsorption (high pressure) and desorption (low pressure), regenerating the CMS for continuous operation. This mechanism is energy-efficient, requiring no heat input (heatless adsorbent regeneration), and is optimized by CMS’s uniform pore structure and high adsorption capacity.

Carbon Molecular Sieves | applications

CMS are widely used in PSA systems for nitrogen generators (DEC.N2G™), serving industries such as:

Carbon Molecular Sieves | advantages and specifications

CMS offer distinct advantages over zeolites (DEC.MZA™), including greater thermal and chemical stability, lower energy consumption, and cost-effectiveness. Their durability ensures long service life in PSA units, often exceeding several years without replacement, provided contamination is avoided.

Carbon Molecular Sieves | conclusions

DEC.CMS™ • Carbon Molecular Sieves: versatile material with a wide range of applications. They are used in a variety of industries, including the chemical, pharmaceutical, and environmental sectors. CMSs are adsorbents [such as DEC.ACA™ (activated carbon), DEC.MZA™ (molecular sieves), DEC.PRA™ (polymeric resins), etc.] which are an ideal tool for specific gas separation. Carbon Molecular Sieves represent a pivotal technology in gas separation, combining high selectivity, robustness, and efficiency. Continuous research enhances their performance, expanding their role in sustainable industrial processes.

Carbon Molecular Sieves | LTKW

Carbon molecular sieves (CMS) transform nitrogen generation, offering unmatched performance across applications. Curious about CMS for nitrogen generation explained? They excel in PSA systems (CMS for PSA nitrogen generation), leveraging kinetic separation for superior carbon molecular sieve N₂ purity. Compare carbon molecular sieves vs zeolites N₂—CMS win with lower costs (CMS N₂ generation cost savings) and higher durability (CMS nitrogen generator maintenance). Check nitrogen generation CMS specifications for technical details, or explore CMS nitrogen generation applications in food preservation and electronics. Looking to shop CMS nitrogen generation online or find carbon molecular sieve suppliers N₂? Our CMS nitrogen generator reviews and cost of CMS in nitrogen generation guide you to the best CMS for nitrogen generation. Learn where to buy CMS for nitrogen generation and unlock the benefits of carbon molecular sieves N2 now!