Ultra Dehydration System | liquid phase

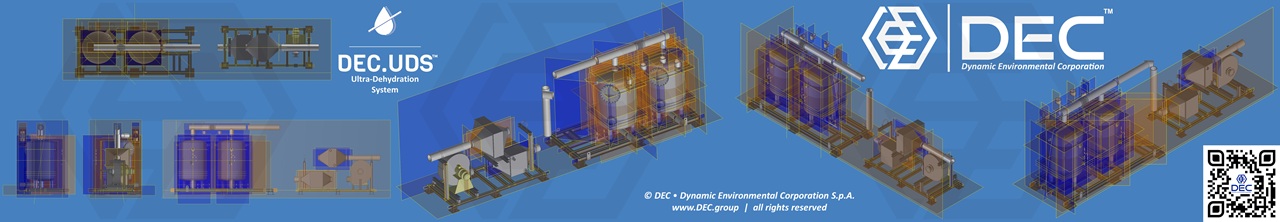

DEC.UDS™

Unlock unparalleled product quality and drastically cut operating costs with the skid mounted DEC.UDS™ (Ultra Dehydration System). As the cornerstone of DEC's Advanced Dehydration Modules (DEC.ADM™), this cutting-edge liquid phase solvent dehydration process leverages molecular sieves (DEC.MZA™) technology to achieve exceptional purity levels. Unlike energy-intensive thermal methods, the DEC.UDS™ provides enhanced dehydration efficiency and minimizes solvent loss, delivering ultra-low residual water content essential for high-performance applications in the chemical, pharmaceutical, and flexible packaging industries. Choose DEC's proven technology for a robust, low operational cost solution that boosts your overall solvent recovery yield and ensures a strong competitive edge globally.

At the heart of DEC's industrial Advanced Dehydration Modules (DEC.ADM™) is the innovative DEC.UDS™ (Ultra Dehydration System) technology. This advanced industrial liquid phase solvent dehydration process is engineered to boost efficiency and cut operating costs significantly.

DEC.UDS™ (Ultra Dehydration System) technology is based on molecular sieves (DEC.MZA™), designed to significantly increase the efficiency while reducing the operating costs.

Industrial processes often involve solvents that require precise dehydration to maintain product quality, while optimizing downstream processes (e.g. distillation processes). Traditional dehydration methods can be energy-intensive, lead to solvent loss, and may not achieve the desired purity levels. These limitations directly impact operational costs and overall process efficiency.

how it works • DEC.UDS™

The foundational technology underpinning the exceptional performance of DEC.UDS™ is its reliance on molecular sieves (DEC.MZA™). Molecular sieves are highly porous crystalline materials with a uniform pore size, allowing them to selectively adsorb molecules based on their size and polarity. In the context of dehydration, DEC.MZA™ molecular sieves are specifically engineered to efficiently capture water molecules while allowing the solvent to pass through unimpeded.

key benefits • DEC.UDS™

The integration of DEC.UDS™ with DEC.MZA™ molecular sieve technology delivers tangible benefits in terms of efficiency and cost reduction:

The DEC.UDS™ Ultra Dehydration System, powered by advanced DEC.MZA™ molecular sieve technology, represents a significant advancement in industrial liquid phase solvent dehydration. By offering unparalleled efficiency, substantial operating cost reductions, and reliable performance, DEC.UDS™ is an indispensable component of modern industrial activated carbon Solvent Recovery Units (DEC.SRU™), enabling businesses to achieve higher quality products, greater operational efficiency, and ultimately, a stronger competitive edge.

contact DEC

If you are looking for a reliable and efficient dehydration process for Solvent Recovery, DEC.ADM™ (Advanced Dehydration Module) is the right and best option: DEC.ADM™ are the most advanced and reliable dehydration units on the market, with processes, configurations and options to meet the needs of different applications, present and future challenges. Feel free to contact DEC: we can help you assess your needs and recommend the best dehydration process for your operation.

LTKW • DEC.UDS™

DEC's leadership in industrial solvent management is defined by the high-quality output of the Ultra Dehydration System. Our molecular sieve technology for high-purity solvent recovery is the ideal alternative or complement to azeotropic distillation for solvent dehydration (IPA. ETA, ETAC) and addresses the strict solvent purity requirements for applications like urethane grade acetates (as Ethyl Acetate, Isopropyl Acetate). The system's benefits include significant DEC Ultra Dehydration System operational cost reduction and proven solvent recovery yield improvement via ultra dehydration. We provide solutions for solvent dehydration systems for the flexible packaging industry and chemical manufacturing solvent recycling, ensuring compliance and a superior solvent quality DEC dehydration guarantee. Technical questions like how to select molecular sieves for solvent dehydration, understanding the molecular sieve regeneration process for solvent drying, and the DEC.UDS™ integration with activated carbon SRU are covered in our comprehensive documentation, demonstrating how to achieve a high performance solvent dehydration technology that easily meets or exceeds fresh virgin solvent specifications.