Brine Chiller Systems

BCS™

In numerous industrial processes, precise and ultra-low temperature control is not just a convenience, but a critical requirement for optimal efficiency, product quality, and safety. When the demand is for chilled glycol water at temperatures as low as -12°C, and even down to -30°C, standard chilling solutions simply won't suffice. This is where BCS™ • Brine Chiller Systems step in, offering robust, reliable, and energy-efficient solutions engineered for the most demanding cold applications.

By combining cutting-edge technology like inverter-controlled screw compressors with a commitment to environmental responsibility through ODP and GWP compliant refrigerants (including ammonia), and offering versatile condenser options, BCS™ Brine Chiller Systems provide a reliable, efficient, and future-proof solution for industrial processes requiring glycol water at temperatures ranging from -12°C down to -30°C.

DEC, a global leader in environmental solutions, offers advanced brine chillers specifically engineered for solvent recovery units. Our robust and reliable cooling systems are crucial for optimizing the efficiency and safety of condensation, distillation, and solvent reclamation processes. Unlike standard chillers, our units coupled with our advanced control algorithms provide precise, low-temperature control essential for condensing volatile organic compounds (VOCs) and reclaiming valuable solvents with high purity. This technology not only dramatically cuts operational costs by enabling the reuse of solvents but also ensures compliance with stringent environmental regulations by minimizing VOC emissions. With an emphasis on energy-efficient design and a commitment to sustainability, DEC brine chillers are the definitive solution for industries seeking to enhance their solvent recovery performance.

environmentally responsible Frigorigenic Fluids • BCS™

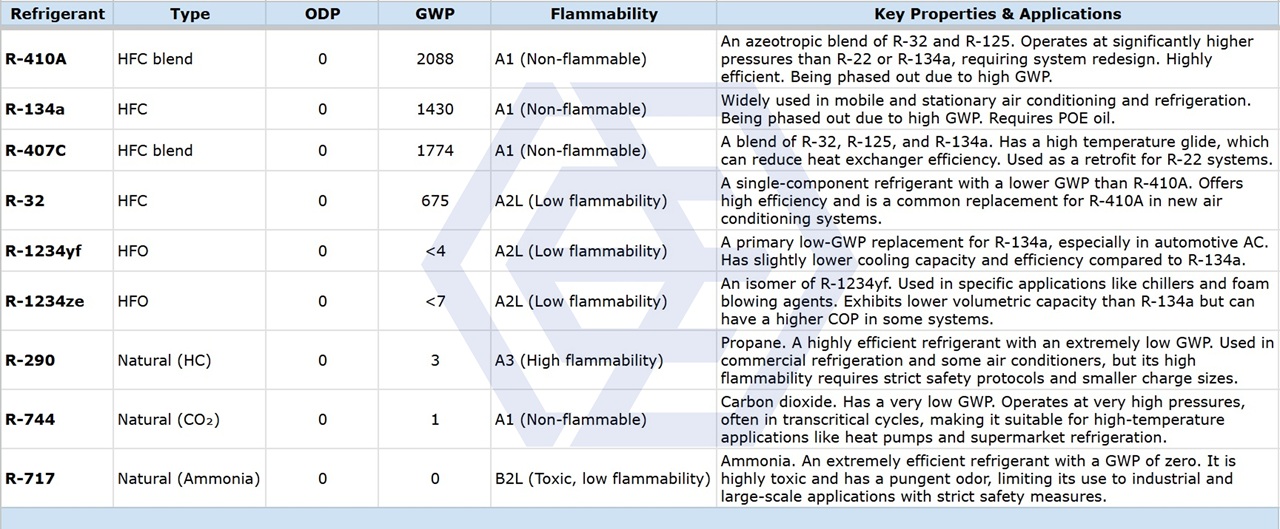

DEC is committed to sustainability, offering BCS™ chiller systems designed to operate with a wide range of frigorigenic fluids (refrigerants), adhering to the latest environmental regulations regarding Ozone Depletion Potential (ODP) and Global Warming Potential (GWP).

Frigorigenic fluids, also known as refrigerants, have two important metrics used to measure their environmental impact: Global Warming Potential (GWP) and Ozone Depletion Potential (ODP).

The BCS™ chillers can be designed to operate with different type of refrigerants, to comply both with local regulations and with capex issues.

Zero ODP & High ODP Frigorigenic Fluids • BCS™

HFCs (HydroFluoroCarbons) have been developed to replace earlier refrigerants like CFCs (ChloroFluoroCarbons) and HCFCs (HydroChloroFluoroCarbons) that had high Ozone Depletion Potential (ODP). HFCs have an ODP of zero, meaning they don't harm the ozone layer. However, they are powerful greenhouse gases with very high Global Warming Potential (GWP).

R-410A, R-134a, R-407C, are all HFCs, a family of frigorigenic fluid of the third generation. While they have an ODP of zero (meaning they don't harm the ozone layer), their GWP is very high. This is a significant environmental concern, and they are scheduled (R-410A, in particular) for phase-out in favor of refrigerants with lower GWP values.

Due to their high GWP, HFCs are being phased out globally under international agreements like the Kigali Amendment to the Montreal Protocol. R-410A, in particular, is being phased out in many countries and replaced by refrigerants with lower GWP values, such as HFOs (hydrofluoroolefins). These newer refrigerants offer a much better balance of performance and environmental friendliness.

Zero ODP & Low ODP Frigorigenic Fluids • BCS™

R-32 (CH2F2)

R-32 is a HFC (HydroFluoroCarbon), also known by its chemical name difluoromethane, a frigorigenic fluid of the fourth generation. This class of refrigerants has been developed to have an ODP (Ozone Depletion Potential) of zero and a significantly lower GWP (Global Warming Potential) than older HFCs. Its GWP=675 is a fraction of the GWP of R-410A (2088), making it a more sustainable alternative. It is classified as A2L for "low toxicity" and "lower flammability" (refrigerants with a burning velocity of less than 10 cm/s), in ISO 817. Due to its favorable environmental characteristics and high efficiency, R-32 is increasingly being used in a variety of air conditioning and heat pump systems. It's particularly well-suited for these applications because of its good thermodynamic performance, including a high volumetric cooling capacity, which allows for smaller charge sizes and more compact systems. It's often used in residential and light commercial air conditioners, where energy efficiency and reduced environmental impact are key requirements.

Zero ODP & Ultra-Low ODP Frigorigenic Fluids • BCS™

R-1234yf (C3H2F4)

R-1234yf is a HFO (HydroFluoroOlefin), also known by its chemical name 2,3,3,3-tetrafluoroprop-1-ene, a frigorigenic fluid of the fourth generation. This class of refrigerants has been developed to have an ODP of zero and an extremely low GWP. Its GWP=4 is a fraction of the GWP of the HFCs, making it a sustainable alternative. It is is classified as A2L for "low toxicity" and "lower flammability" (refrigerants with a burning velocity of less than 10 cm/s), in ISO 817. Due to its favorable environmental and safety characteristics, R-1234ze is increasingly being used in mobile air conditioning (MAC) systems for vehicles and residential air conditioning systems. It's particularly well-suited for these applications because of its good thermodynamic performance and ability to operate efficiently in a wide range of conditions. It's particularly well-suited for these applications because of its good thermodynamic performance and ability to operate efficiently in a wide range of conditions. It's often used as a replacement for R-134a.

R-1234ze (C3H2F4)

R-1234ze is a HFO (HydroFluoroOlefin), also known by its chemical name trans-1,3,3,3-tetrafluoroprop-1-ene, a frigorigenic fluid of the fourth generation. This class of refrigerants has been developed to have an ODP of zero and an extremely low GWP. Its GWP=7 is a fraction of the GWP of the HFCs, making it a sustainable alternative. It is is classified as A2L for "low toxicity" and "lower flammability" (refrigerants with a burning velocity of less than 10 cm/s), in ISO 817. Due to its favorable environmental and safety characteristics, R-1234ze is increasingly being used in large-scale chillers and heat pumps. It's particularly well-suited for these applications because of its good thermodynamic performance and ability to operate efficiently in a wide range of conditions. It's often used in industrial processes, where large cooling capacities are required.

Propane (C3H8)

Propane is a "natural refrigerant" (hydrocarbon, part of the Earth's biogeochemical cycles). It is one of the most environmentally friendly refrigerants available, with an ODP of zero and a GWP of just 3. Its use is expanding rapidly, especially in small commercial refrigeration, due to its minimal environmental impact.

Propane is classified as A3 for "low toxicity" and "higher flammability", in ISO 817 and EN 378 standards), which requires strict safety protocols for handling and equipment design. The Lower Explosive Limit (LEL) for propane is around 2.1% by volume in air: this means that if the concentration of propane in the air reaches this level, it can ignite and cause an explosion. Propane is heavier than air, so a simple leakage would cause the gas to pool in a low-lying area, creating a highly explosive atmosphere. To mitigate this risk, propane chillers shall be designed with numerous safety features, and their components must meet specific standards: propane BCS™ chillers must be installed with specific separation distances from potential ignition sources (such as electrical equipment, solvent storage tanks, combustion appliances, or open flames), to mitigate explosion risk.

There are strict international and national standards that limit the maximum amount of propane a chiller can contain based on the room's volume and ventilation rate. For smaller rooms, this often means a much lower refrigerant charge is required, which may limit the chiller's cooling capacity or amndate an outdoor installation.

Carbon Dioxide (CO2)

R-744 (Carbon Dioxide) is a "natural refrigerant" (a fundamental component of the Earth's natural carbon cycle). It's one of the most environmentally benign refrigerants available, with a zero Ozone Depletion Potential (ODP) and a Global Warming Potential (GWP) of just 1. Its use is rapidly expanding, particularly in supermarkets, industrial refrigeration, and heat pumps, due to its excellent thermodynamic properties and minimal environmental impact.

HR-744 is classified as A1 for "low toxicity" and "no flammability" in ISO 817 and EN 378 standards. The main safety consideration for R-744 is its high operating pressure. Systems using R-744 can reach pressures of over 100 bar (1,450 psi), requiring strict safety protocols for handling and equipment design.

Because R-744 is heavier than air, a leak in a confined space could cause oxygen displacement, leading to asphyxiation. To mitigate this risk, R-744 systems must be designed with numerous safety features, and their components must meet specific standards. The installation must also include proper ventilation and CO2 gas detectors to ensure safety. The high pressures require robust components like specialized compressors, high-pressure-rated pipes, and relief valves, ensuring the system can operate safely and reliably.

Zero ODP & Zero GWP Frigorigenic Fluids • BCS™

Ammonia (NH3)

R-717 (Ammonia) is a "natural refrigerant" (inorganic compound, part of Earth's nitrogen cycle). It has been a leading refrigerant in industrial applications for over a century due to its exceptional efficiency. Environmentally, it's an excellent choice, with an Ozone Depletion Potential (ODP) of zero and a Global Warming Potential (GWP) of zero. Its use is widespread in large-scale industrial operations like food processing, cold storage, and chemical manufacturing.

However, safety must be a top priority with ammonia systems. Ammonia is a toxic substance (classified as B2L for "high toxicity" and "lower flammability" (refrigerants with a burning velocity of less than 10 cm/s), in ISO 817), and in high concentrations, it is also flammable. A significant advantage is that ammonia is lighter than air, so a leak will cause it to rise and dissipate rather than pool in low-lying areas. The pungent odor is another critical safety feature, as it's easily detectable even at low, non-hazardous concentrations, providing an early warning system.

While ammonia is combustible, it is difficult to ignite. Its Lower Explosive Limit (LEL) is very high, at around 15% by volume in air. This means a substantial amount of ammonia must be present in the air for it to be flammable. Despite this high LEL, ammonia still represents a critical safety concern due to its toxicity and flammability. Therefore, the use of ammonia requires strict safety protocols, including specialized, robust equipment, leak detection systems, alarms, and ventilation to protect personnel and mitigate risks.

There are strict international and national standards that limit the maximum amount of ammonia a chiller can contain based on the room's volume and ventilation rate. For smaller rooms, this often means a much lower refrigerant charge is required, which may limit the chiller's cooling capacity or amndate an outdoor installation.

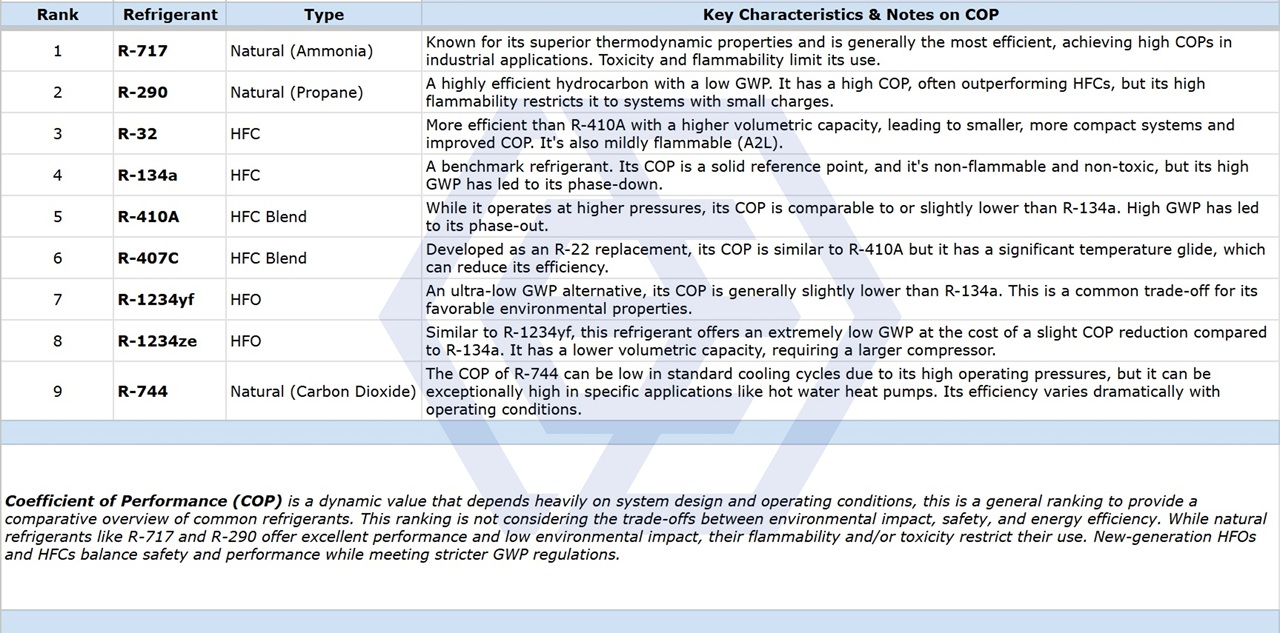

Performance of Frigorigenic Fluids • BCS™

While the Coefficient of Performance (COP) is a dynamic value that depends heavily on system design and operating conditions, here is a general ranking to provide a comparative overview of common refrigerants:

This ranking is not considering the trade-offs between environmental impact, safety, and energy efficiency. While natural refrigerants like R-717 and R-290 offer excellent performance and low environmental impact, their flammability and/or toxicity restrict their use. New-generation HFOs and HFCs balance safety and performance while meeting stricter GWP regulations.

chiller condenser configuration • BCS™

A chiller's condenser is a vital component that rejects heat from the refrigeration cycle. BCS™ (Brine Chiller System) offers two primary condenser configurations to suit different operational needs and environmental conditions: water-cooled and air-cooled.

BCS™ provides flexibility in condenser configurations to suit diverse operational environments and energy considerations:

Water-Condensed chillers

Water-condensed, or water-cooled, chillers are known for their high energy efficiency, especially in large-scale applications and hot climates. They use a DEC.CWS™ • Cooling Water System (e.g. cooling towers or free coolers) to reject heat, which cools the condensing water through evaporation. This process allows the chiller to condense at lower temperatures, reducing the work required by the compressor and thus saving energy. Although they require a dedicated water supply and associated infrastructure, their long-term operational savings and extended equipment lifespan often make them the most economical choice.

Air-Condensed chillers

Air-condensed, or air-cooled, chillers are an excellent choice when water is scarce, expensive, or of poor quality. These chillers reject heat directly into the ambient air using large fans, eliminating the need for a separate cooling water system. While their efficiency can fluctuate with high ambient air temperatures, recent improvements in fan and coil technology have greatly enhanced their performance. Their simplicity of installation and operation, without the need for water treatment or a cooling tower, makes them ideal for a wide range of applications.

Refrigerant Retrofit • BCS™

When retrofitting a refrigeration system to use a new refrigerant, it is essential to consider more than just the ODP, GWP, and COP. The process is not a simple "drop-in" replacement and requires careful evaluation of the system's components to ensure safety, reliability, and efficiency.

Refrigerant Selection: What Frigorigenic Fluid is Best for You? • BCS™

Selecting a chiller involves a complex balance of performance, regulatory compliance, and long-term operational costs. While BCS™ chillers offer adaptable refrigerant options to meet various cooling needs and regulations, the ultimate decision should also weigh the critical importance of a manufacturer’s reliable service network. The availability of a strong, local service and maintenance infrastructure can significantly impact the total cost of ownership and ensure consistent, long-term performance, often outweighing minor differences in initial performance metrics.

While factors like Ozone Depletion Potential (ODP), Global Warming Potential (GWP), and Coefficient of Performance (COP) are crucial for refrigerant selection, the most fundamental consideration is the specific application, particularly the chilling temperature or evaporator temperature. A refrigerant's thermodynamic properties, like its boiling point and operating pressures, must be suitable for the required temperature range.

Selecting a refrigerant with an inappropriate boiling point will result in a poorly functioning system, either by failing to reach the target temperature or by operating at inefficiently high or low pressures, which can damage the equipment.

Contact DEC!

For more information on DEC's VOC sustainable emission control solutions, interfaced with BCS™ • Brine Chiller Systems, please contact DEC.

LTKW • BCS™

DEC’s brine chiller systems are designed to meet the diverse needs of various industries, from chemical manufacturing to pharmaceutical solvent recovery and ethanol solvent recovery. We provide solutions for both air-cooled and water-cooled applications, featuring advanced designs that are often explosion-proof for handling flammable solvents. Our chillers are compatible with a range of refrigerants, including eco-friendly options, and are engineered for seamless integration with solvent recycling processes and distillation. We address a wide range of requirements with units that offer varying cooling capacities and can handle diverse coolants like propylene glycol. Whether you are considering a new brine chiller system design or looking to upgrade an existing solvent recovery unit, our technology is built for optimal performance. We provide low temperature solutions for complex applications like high-purity solvent recovery, along with custom brine chillers to suit your specific needs. Our comprehensive offering covers every aspect, from the cost of brine chillers to long-term maintenance and integration with remote monitoring capabilities, making DEC the top choice for an efficient, safe, and cost-effective solvent recovery unit with an integrated brine chiller.