DEC.WTE™

waste to energy

DEC.WTE™ • waste to energy

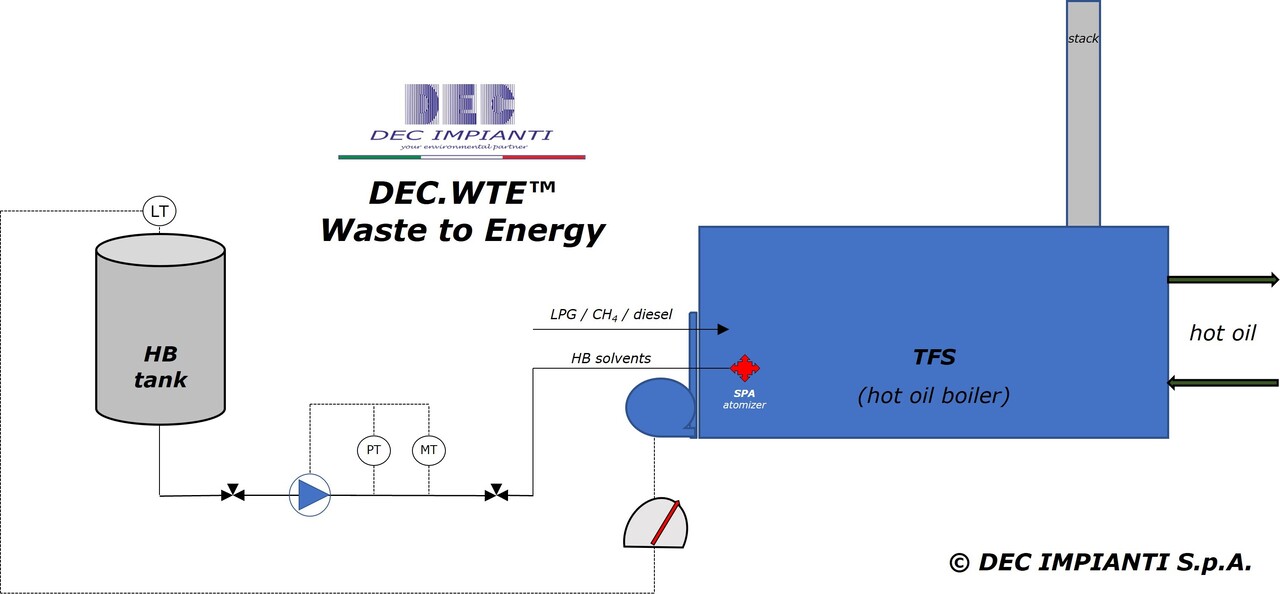

Depending on the quantity (%) of retardants used in converting operations, a quantity of HB products will have to be disposed-off, representing a cost. As an alternative, a properly equipped TFS module (hot oil boiler), may use the mixture of “HB” solvents, as an alternative fuel, saving an important amount of money, drastically reducing the fuel consumptions (and the resulting thermal energy).

DEC.WTE™ (waste to energy) systems are a valuable tool for reducing pollution and generating renewable energy. They can be used to burn a variety of waste materials, including solvent waste. Solvent waste is a type of industrial waste that is often generated from distillation columns. It can contain high-boiling solvents, such as methoxy propanol, ethoxypropanol, acetic acid.

DEC.WTE™ systems can be used to burn solvent waste in a boiler to generate heat. The heat can then be used to generate electricity or steam. This can help to reduce the amount of fuel that is burned in the boiler, which can save money and reduce emissions.

DEC.WTE™ systems can help to generate renewable energy: the heat that is generated from burning solvent waste can be used to generate electricity or hot oil or steam: this can help to reduce the reliance on fossil fuels and promote a more sustainable energy future.

DEC.WTE™ systems can help to save money. By burning solvent waste in a DEC.WTE™ system, businesses can reduce the amount of fuel that they need to purchase. This can save money on energy costs.

Overall, DEC.WTE™ systems are a valuable tool for reducing pollution, generating renewable energy, and saving money. They can be used to burn a variety of waste materials, including solvent waste. If you are looking for a way to reduce your environmental impact and save money, consider using a DEC.WTE™ system to burn solvent waste.