LEL control systems | automatic recirculation systems

DEC.LEL™

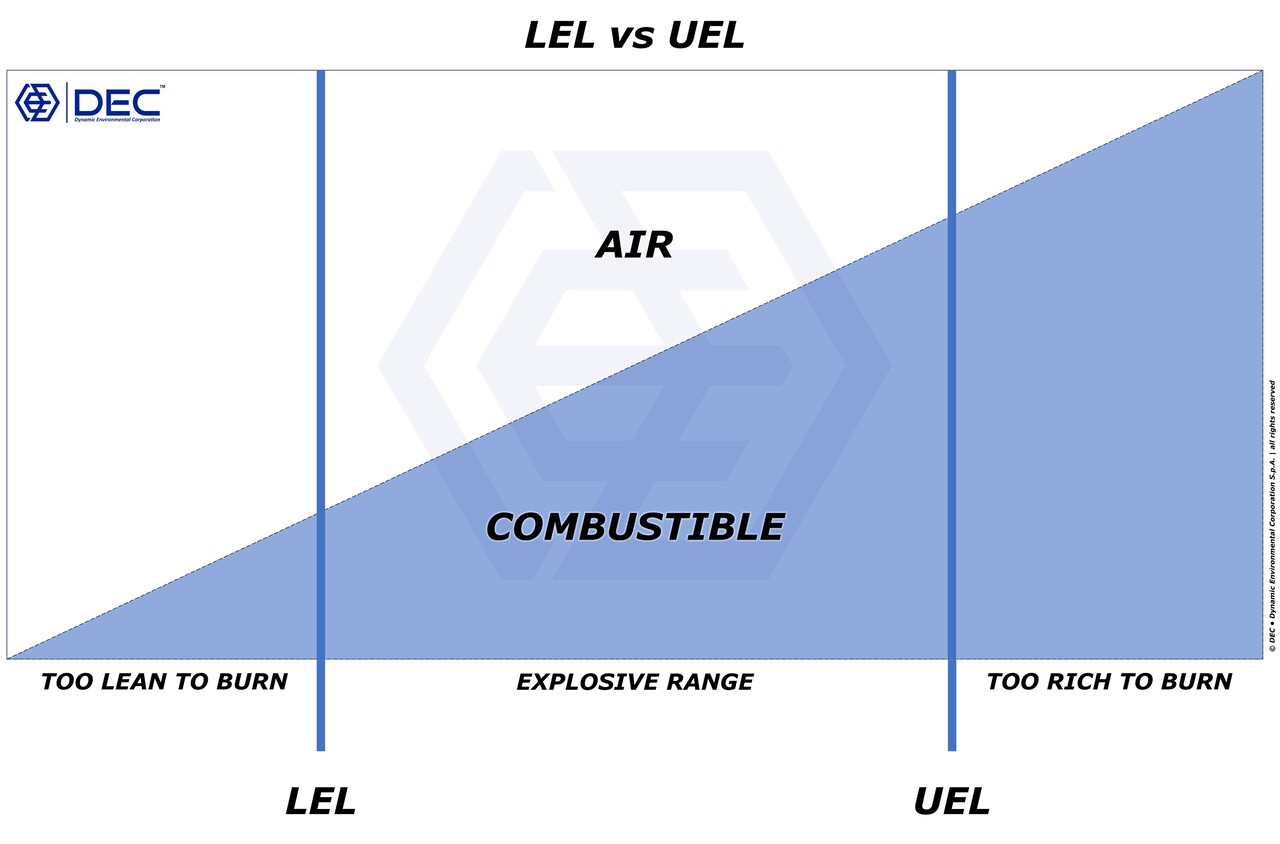

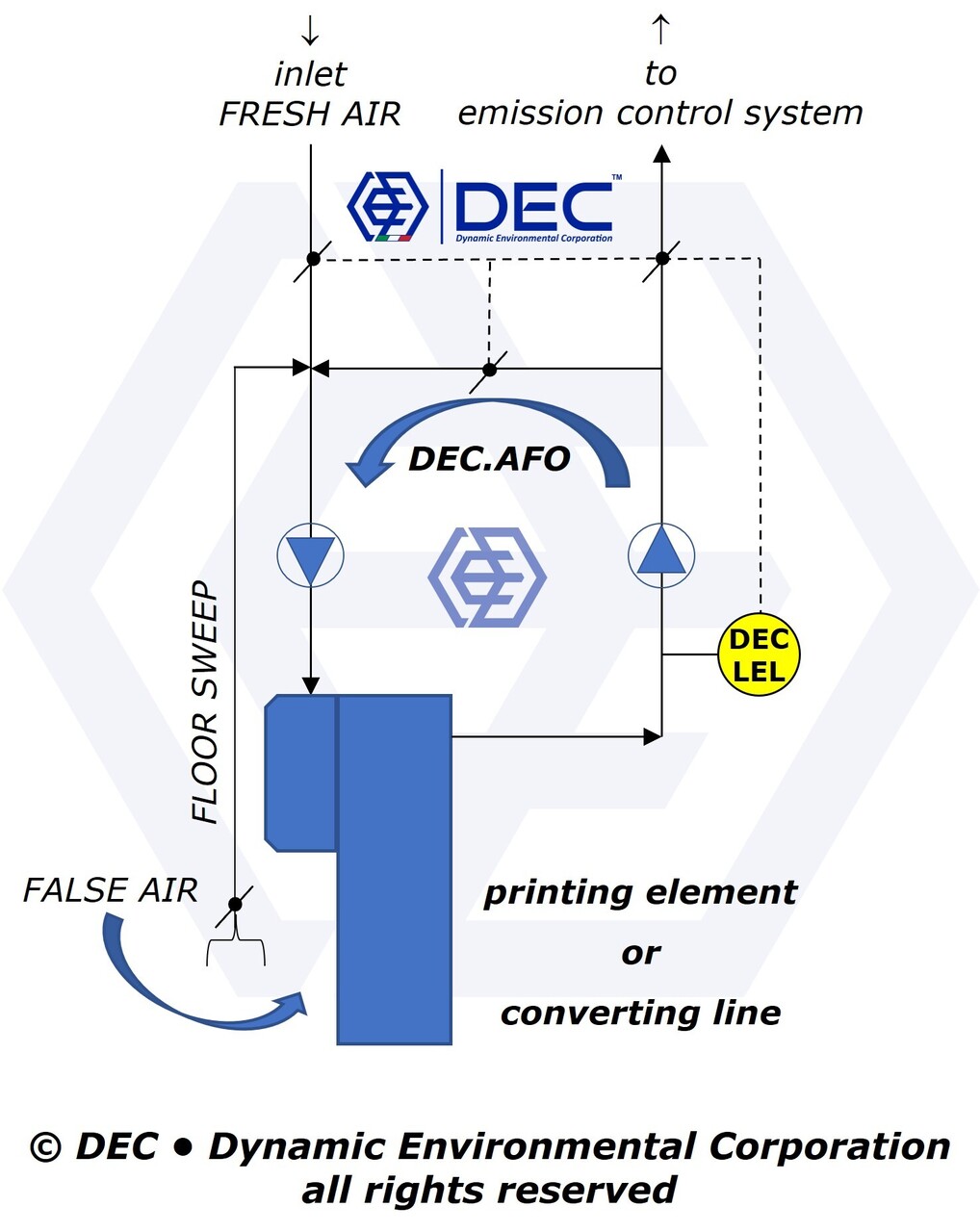

LEL (Lower Explosive Limit) monitoring and automatic recirculation systems are mandatory when you are planning to install a VOC emission control system (e.g. a solvent recovery unit, or a thermal oxidizer). Furthermore, increasing energy costs, are requesting our customers (flexible packaging and converting industries, using rotogravures, flexo and lamination machines) to explore and evaluate energy saving technologies, in order to increase their competitiveness in the global market.

DEC.LEL™ • benefits

Thanks to DEC.LEL™ recirculation system, we can reach:

DEC.LEL™ • LEL control systems

Three different LEL control and recirculation processes are available:

LEL Monitoring Technologies

The following LEL monitoring technologies are part of our portfolio: