Activated Carbon • from ancient medicine to air pollution control

A Historical Timeline

The history of activated carbon's use for adsorption is a rich and diverse one. Its properties as an effective adsorbent for removing pollutants have been recognized since ancient times. From its earliest medicinal applications to its role in air pollution control, activated carbon has played a significant role in various industries throughout history.

Ancient times

Activated charcoal has been used for medicinal purposes since ancient times.

The first recorded use of activated charcoal for medicinal purposes was in Egyptian papyri around 1500 B.C.: the Egyptians used charcoal to treat a variety of ailments, including intestinal ailments, unpleasant odors, and water purification.

In the 4th century B.C., the Greek physician Hippocrates also used activated charcoal to treat a variety of aliments, including food poisoning (and related diseases).

In the 1st century A.D., the Roman physician Pliny the Elder also wrote about the medicinal uses of activated charcoal.

18th and 19th century

Then adsorption skills of activated carbon were discovered in the late 18th century: in 1773, Carl Wilhelm SCHEELE (DE) discovered the adsorptive power of charcoal in the liquid phase. He found that charcoal could be used to remove impurities from water, such as bad taste and odors. In the following years, in 1785, Johann Tobias LOWITZ (DE-RU) studied the industrial application of charcoal in various aqueous solutions for the removal of bad taste and odors from water, including dyes removal and decolorization (removal of organic and inorganic pollutants).

As the potential applications of activated carbon grew, methods of activation had to be developed at an industrial level. In 1865, John HUNTER (UK) prepared activated carbon from coconut shell and studied adsorption of gases on it, while in 1881, Heinrich KAYSER (DE) firstly used the term "adsorption" to describe the process by which gases are attracted to and held on the surface of a solid.

In 1892, Henri MOISSAN (FR) [Nobel Prize in Chemistry, 1906] developed the process of steam activation, which is still used today for producing activated carbon: this process involves heating charcoal in the presence of steam, which creates a porous structure that is highly adsorbent. The main advantages of steam activation are that it is a relatively simple and inexpensive process (but time taking), and it can be used to create a wide range of highly porous carbons with different properties, more effective at adsorbing gases and other pollutants, and leading to a widespread use of activated carbon in a variety of industrial applications.The work of these scientists helped to lay the foundation for the development of activated carbon as a commercial product. Their studies showed that activated carbon was an effective adsorbent for a wide range of gases, and they helped to develop methods for the production of activated carbon with specific properties.

20th century

The first known use of activated carbon for gas phase adsorption was in the early 1900s, when in 1913 it started to be employed in filtering harmful and poisonous chemicals, through gas masks during the two world wars (WW1 and WW2), highlighting its ability to adsorb harmful gasses and protect soldiers from chemical warfare agents.

As the petrochemical companies started their activities (1920s), natural gas field facilities or refineries were in need of activated carbon for their processes: this boosted the demand and determined CECA | Carbonisation Et Charbons Actifs (FR) to be incorporated, in order to meet the growing demand of activated carbon.

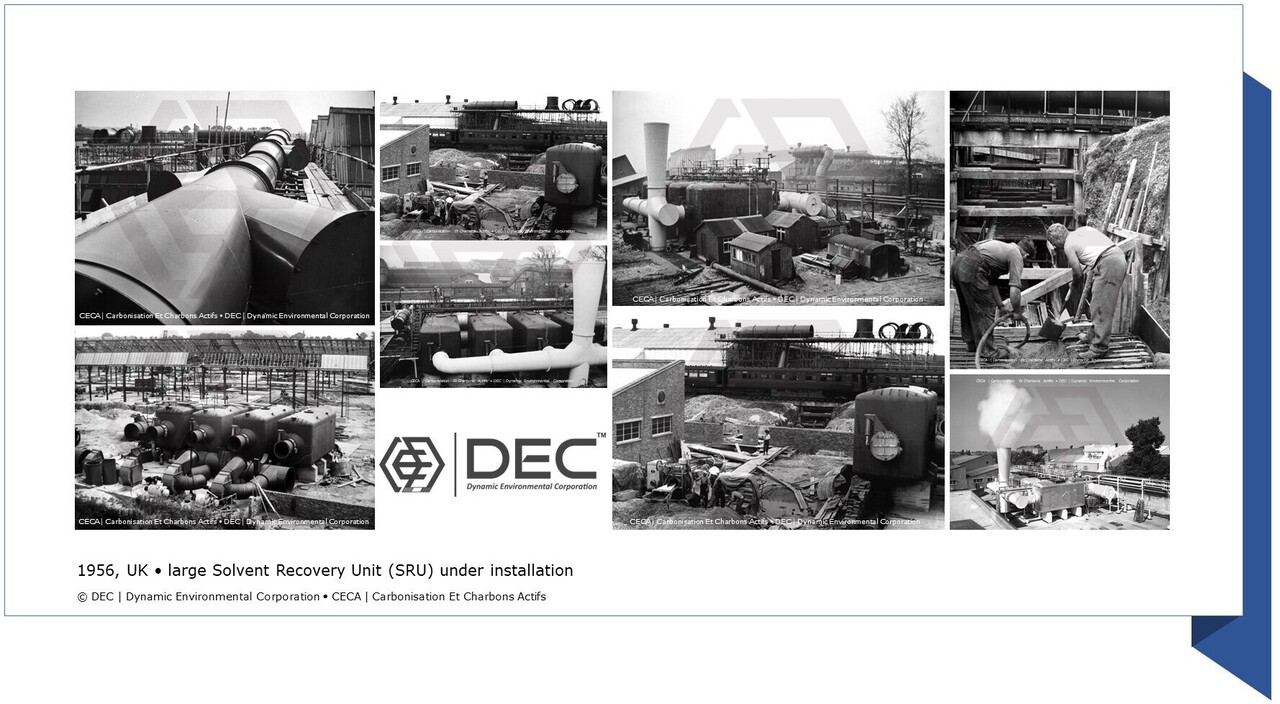

As DEC (Depurazione Emissioni Convogliate, nowadays Dynamic Environmental Corporation, IT) was incorporated (1946), specializing in the design, engineering, manufacturing, installation, and maintenance of advanced air pollution control systems and technologies, the boundaries of SRUs and gas phase adsorption were pushed beyond the traditional schemes.

In the 1960s and 1970s, environmental regulations such as the US Clean Air Act led to increased focus on air pollution control. Activated carbon emerged as an essential tool for controlling VOC emissions from automotive (EVAP • Evaporative Emission System) and industrial facilities (SRU process).

In 1988, DEC (IT) and CECA (FR) sealed their long-lasting cooperation into a strategic alliance. CECA to focus on the development, production and supply of adsorbents (activated carbon and molecular sieves), while DEC to develop eco-friendly environmental applications and develop advanced adsorbents' on-site regeneration technologies. DEC took over CECA's existing customer base for gas phase adsorption VOC recovery units, inheriting the full references of existing SRUs and the related business of engineering, construction and service (including revamping and retrofit): this partnership focused on large industrial applications of VOC recovery units (focused on reducing air pollution and greenhouse gas emissions). A strategic move to address global sustainability and decarbonization challenges by focusing on innovative, sustainable technologies and research.

Over time, DEC became the largest supplier of industrial VOC emission control systems, with solvent recovery. The SRU systems are designed to recover organics for direct reuse in the process, which is the most sustainable option for industries that emit a high quantity of organics. DEC has also developed advancements in on-site regeneration techniques (e.g. RSV™ • TSA steam, RSG™ • TSA inert gas N2, and RTV™ • T+VSA vacuum), making the process more cost-effective and sustainable.

present

In recent decades, activated carbon has continued to be used in diverse applications, including solvent recovery units (SRU) from gas streams in various industries like petrochemical, pharmaceuticals, adhesive tapes, helio printing, and food packaging.

Today, activated carbon remains a widely used and effective method for gas phase adsorption and solvent recovery due to its versatility, high adsorption capacity, and ability to be regenerated for multiple uses. Its history reflects its significance in ensuring cleaner air and the efficient recovery of valuable solvents in industrial processes.